The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2018-02-01 - Rapido F40PH

Category RandallThe main passenger automation runs using two new Rapido F40PH engines. They have superb detail and superb sound.

Since we use them for the automation in a back-and-forth route, our initial concern was that some dirty track where the engine stops and reverse would have them lose power. Thus we got two ESU current keeper which I installed.

Many weeks pass and I finally complete the automation of the route. At first everything is fine and then we realize quickly that one engine derails consistently in one of the curves, just before the canyon bridge by the entrance.

Oddly enough we have seen hundreds of engines go through that route, and even though the layout track is not exactly new, it does seem OK.

It’s a short train yet to avoid shoving light coaches on the way back, we have two engines which we run in a push pull configuration. It also looks way better that way. One of my concerns was speed matching so I spent quite some time matching them as out of the box both engines were not matched at all.

We try a few variations and finally settle on simple slowing down the engine after the Sonora turnout and that seems to fix it. I run all the automation on a 28-speed scale with full speed at 20, and slowing down to 16 or 12 seems to do the trick. We take the conservative approach and here we go:

This was filmed in January 2017 and at that point we took it for granted. The little speed change did the trick, we were done. We continued running it once in a while for the following months, and we got two more derailments in other parts, each when . Both times I find the front snow plows have vanished

Forward to December 2017. We did not have access to the layout for the last 4 months, a good portion of the automated route was covered by wood dust. We first spent a couple weeks vacuuming all we can and running the track cleaning engines & cars. Eventually we’re ready to make sure the automation works as it before, just a routine check.

To our surprise, the engines derail again on the same spot. One seem to derail a bit more than the other so we swap them around, and we try again. Now they would derail somewhere else and the more I’d run them, the more they would derail in unexpected (and hard to reach!) locations.

We contacted Rapido to try to figure if this was a known issue. We even sent the engines back for inspection and they came back OK -- supposedly something was changed but I could really not tell what except one decoder didn’t have my speed match settings anymore. Still, even after, the inspected engines continued derailing.

At that point I decided to take the matter seriously and I developed a theory. Two places where the engine derails at the club are large right curves. One realization I had is that they have some superelevation built into the curve. It's a fairly subtle elevation (as it should) but there clearly is one.

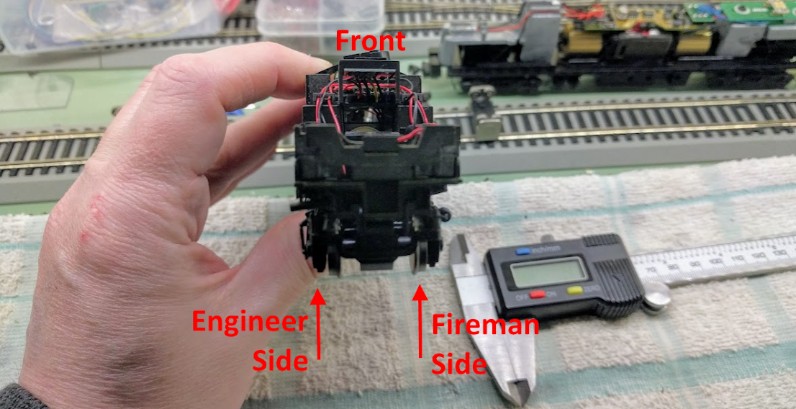

So what happens when the engine is tilted a bit sideways? I did some experiments at home and on the track at the club. As soon as the engine is tilted to the right , I could clearly see the front left wheel lift with the chassis as soon as the engine is tilted a bit to the right. However if I tried to tilt it in the other direction, the front right wheel would keep on contact with the rail or roller support.

Pushing on the truck in the direction of the arrow would show that one side had some play (1 mm or so) whereas the other one had no play at all.

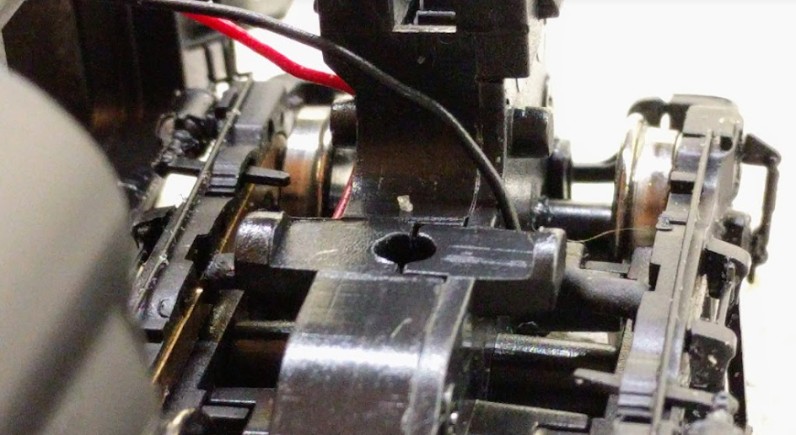

My conclusion is that compared with other engines I have around (including the Rapido RDC), the trucks on the F40PH have almost no sideways pendular motion. This does seem to have do with vertical tolerance on the truck support.

That could explain why as soon as the engine is tilted to the right, the left front wheel lifts and that's enough to make it jump the rail on a left curve.

So now, how can we fix this?

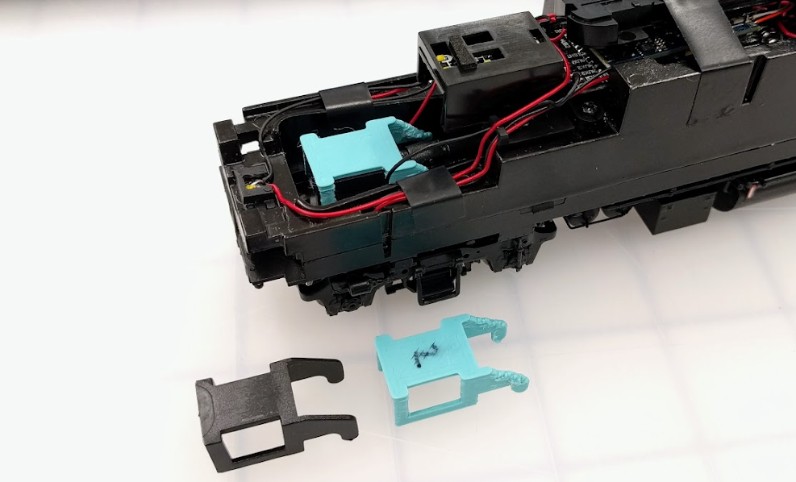

On these trucks, like pretty much any modern HO engine, the cover for the worm gear on the truck also acts as a support that balances the truck on the chassis. My first experiment was to create a variation on the worm gear cover where the part that lies on the chassis is a bit higher, providing more play. Here’s the result of a crude 3d print copy of the worm gear cover:

That did some to fix part of the issue. Now the engines could go at higher speed in the spots where it derailed before.

This wasn’t enough yet as I could routinely see the engines derailing in two other spots, and each time always left curves.

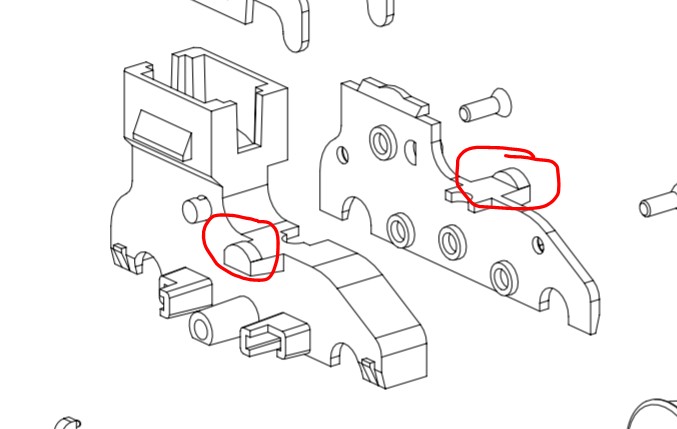

So digging a bit more, I looked at the trucks even more closely, comparing them with the parts schema:

The two little round parts is where the chassis rests on the truck. They should have the same size, but one is noticeably larger than the other one. More important I think, they do not have the same height, one measures 0.2 mm higher than the other one. The suggested fix is thus to file them carefully so that they have the exact same height.