The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2018-12-12 - Randall Repairs: Turnout T161

Category RandallAffected |

Turnout T161 (end of siding between Bridgeport & Sultan). |

Description |

Intermittent loss of power on frog. Eventually turnout motor stopped. |

Summary Fix |

Replaced Fulgurex motor by another one. |

Description of Issue

We’ve had engines stop-and-go on turnout T161 for several months, especially steam engines, or short non-MU engines. The turnout was always in the normal position when this happened.

The turnout is hard to access as it’s more than 3 feet away from fascia, and the only other access is above the adjacent mainline which partially covers the turnout motor.

Frog & track power measured 11.8 V in this area. Frog power was consistent, except when engines were stopped where it would drop to about 3 V.

The turnout motor is a Fulgurex. The frog polarity is determined by a 2-contact inverter that closes on the Fulgurex as the motor throws in one direction or the other.

As with other Fulgurex & twin-coils turnouts on this layout, one typical issue is corrosion of the 2 contacts, either creating a bad contact or a corroded resistive one (see repair to T130). One way to fix this is a dash of CRC 2-26 and trying to clean the contacts. This was made hard by the location of the turnout.

Another issue I found with the Fulgurex is that the spring on the 2-contact inverter can dismount and jump off. This was the issue on T05. It was quite hard to put it back in place and that’s when I had close access to the Fulgurex.

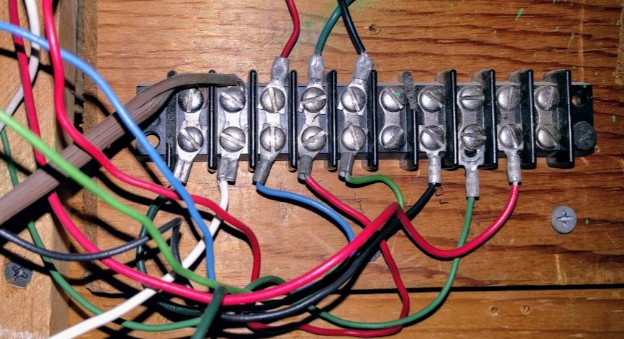

Original terminal block for this turnout

Top of the terminal connects to the turnout toggle (brown house wire) and to the track.

Bottom of the terminal connects to the Fulgurex contacts.

Terminal block for this turnout motor, from left to right:

- Fulgurex Dark Green ⇒ to Brown house wire side 1. +/- 10 V DC command.

- Fulgurex White ⇒ to Brown house wire side 2. +/- 10 V DC command.

- Fulgurex Blue [Contact 1 Right] ⇒ to Red rail feed wire.

- Fulgurex Red [Contact 1 Middle] ⇒ to frog feed wire.

- Fulgurex Green [Contact 1 Left] ⇒ to Black rail feed wire.

- Fulgurex Black [Contact 2 Right] ⇒ N/C.

- Fulgurex Green [Contact 2 Middle] ⇒ N/C.

- Fulgurex Red [Contact 2 Left] ⇒ N/C.

Description of Fix

The first attempt was to throw T161 in reverse. The motor was working and the turnout would throw nicely. Frog changed polarity as needed, which meant the inverter spring was intact. However trains continued to stop.

The second attempt was to spray a bit of CRC 2-26 on the inverter contacts. After that I realized the turnout would not throw anymore. The Fulgurex properly received the +/-10V on its inputs but it wasn’t moving. On a Fulgurex, the motor starts & stops based on the position of another 2-contact inverter. It’s possible I pushed on it with the CRC 2-26 sprayer, preventing it from forming the adequate contact.

Since the turnout was no longer throwing, the third suggested attempt was to wire the frog directly to the proper polarity rail power. By bypassing the Fulgurex altogether, this has the advantage that it would make it clear whether the electrical issue is in the Fulgurex or elsewhere like the track/frog feed wires.

As a quick test, green frog wire is hardwired to the black rail feed wire

This was done and the test train worked beautifully without a glitch.

Since the Fulgurex was now a clear culprit -- and the motor didn’t even throw anyway, I simply removed it by unscrewing the 3 screws holding it to the wood support. This makes it relatively easy to remount and realign it the same way.

Testing the Fulgurex with a 10 V DC power supply showed that it would not throw.

We have a dozen Fulgurex or so in a box in one of the cabinets. These were removed when they switched part of the mainline to Tortoise slow-motion turnout motors. After trying a couple of them, I found one which motor was working and the 2-contact inverter was working too. It did make some shrieking sound when throwing. This was addressed by spraying a tiny bit of CRC 2-26 in the motor -- hopefully the collector will get some -- and I found some dry lubricant which I put on the worm drive. That removed the shrieking and should help bring a new life to this legacy hardware.

Once I validated the new Fulgurex was working OK on the workbench, I proceeded to install it on the track.

Wiring color for the new T161 Fulgurex:

- Yellow / Green: +/-10 V DC power to motor.

- Black [Contact Right] ⇒ to Red rail feed wire.

- Red [Contact Middle] ⇒ to Green frog feed wire.

- Green [Contact Left] ⇒ to Black rail feed wire.

Once installed, I did a continuity test with the layout power turned off to make sure the frog had the proper polarity. After turning on power, validated that the frog matched the proper rail polarity in both normal/reverse positions.

Fix time: 3 hours.