The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

2019-03-09 - Randall Repairs: Branchline Sonora Station

Category RandallAffected |

Branchline Sonora Station B830 to B820. |

Description |

Dead spot in front of Sonora Station. |

Summary Fix |

Resolder track joiner. |

Description of Issue

Still having some small trouble running RDC ATSF on the Branchline. Two weeks ago I fixed a turnout issue and thought that would be the last of it. Now we have a dead spot, and I’m trying to address that.

RDC ATSF on the dead spot on the Branchline

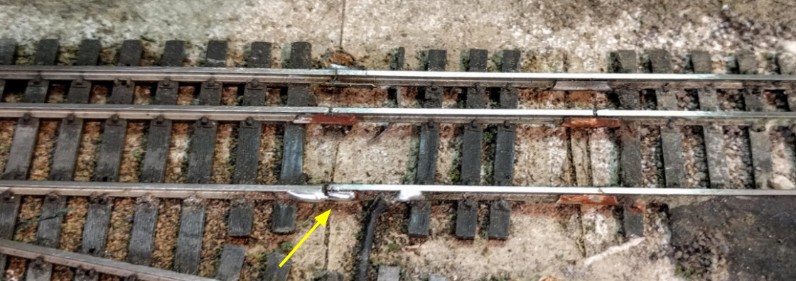

Looking at it more closely, the track feeder is on the right; next to it on the left is a small 2 inch piece of track then the turnout. Power for the turnout rails comes from the track attached to it.

The problem is with the joiner, or rather the lack of it. It looks like there was one, but all I can see is a tiny gap in the track.

A quick test showed that it’s the outside rail that has a bad connection and the inside rail (common) was fine.

Description of Fix

Working on this part of the layout was challenging. It’s too far to work from the fascia, and there’s an access hole next to it that is quite narrow so here I am soldering at arms’ length, it’s difficult to get close to the track, and I can’t see what I was doing from that angle since I had to solder the rail on the side away from me.

Eventually I got the work done. At first it did seem fine but taking a closer picture later from the other side showed that I may not have gotten a good connection on one side of the joint:

That solder doesn’t look good on the right side. It did work on the spot and for the next few days, and then I started having a dead spot again. So now I need to go back to it and finish the job properly. I think using a bond wire should be more reliable than trying to solder on the obviously oxidized rail.

Update 2019-03-11:

That fix didn’t last very long and the automation stopped due to lack of connectivity a day later, so in the evening I went back at it, this time using a little mirror to (vaguely) see what I was doing:

And now the RDC is working yet again.

I will have to look at some weathering to make the shiny solder a tad less obvious. Or time will take care of it.

Should I be worried that all the rail joiners look rusty? Since this work seems to date from 1991, they are not even 20 year old...