The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2019-11-07 - Follow up on Warped Track Maintenance

Category RandallBack in the “Warp Drive” entry from 11-02, I was mentioning how some of the track from Napa yard had very badly warped.

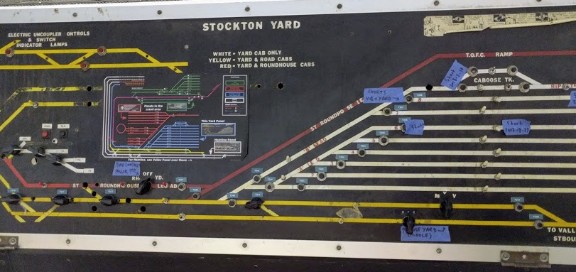

It is worth noting the warping issue also somewhat affected the Richmond yard. I had also noticed that somehow the front panel of the Stockton Yard panel had a similar issue, the panel no longer laying flat on its support.

Today I got it to work on this, and to my surprise the track had started fixing itself, here’s a side-by-side comparison:

Napa Yard Before |

Napa Yard After |

Richmond Yard Before |

Richmond Yard After |

Also the front panel of the Stockton Yard panel was not warped anymore:

One thing that is not shown on the yard pictures: the expansion on the ladder side of the Napa yard was severe enough to push one of the turnouts outer rails. This made the turnout short as the point would touch the wrong rail when thrown. And of course it made the turnout not in gauge anymore. There was enough force to break the plastic tabs holding the track on the turnout ties, so I’ll have to spike the rail.

Since the Napa yard is easy to access, I started working on it. My guess is that there is either track expansion or shrinkage of the wood bed support somehow. Either way, the track lacks expansion gaps. My first idea was to remove all the nails holding the track -- the yard track is obviously not glued there, just nailed, and a quick test showed me I could easily pull the nails carefully using flat cutters. I was careful not to break any tie, and collected all the nails without damaging them which means I can reuse them later. This was easy in the exposed area, but then I reached the part where the track is under the Bridgeport Yard, and the lack of clearance and distance made it impossible to neatly remove the tie nails.

At the end of the Napa yard ladder, there are huge blocks of foam. I’m guessing to act as a nice buffer. To my surprise they also contain a big screw in them and they were glued in place with the end of the track. To make an expansion gap, the easiest thing to do is simply cut the track in front of the glued part using a rail handsaw:

As soon as I did that, the rails tried to expand by about one millimeter, not fitting in the gap anymore:

That part is fine. It just means I need to file/cut the rails a bit more and place a rail joiner in there. Then I can nail the ties back in place.

On the other side of the yard, we have the ladder. Careful examination showed the track joins the turnouts using isolated track joiners. But also removing the tie nails in the accessible area, I had no problem sliding the track out of the joiners:

As can be seen in the picture above, as soon as I did that, the track also expanded, and it would not fit in the space available.

Unsurprisingly, that also instantly straighten the track:

Thus my goal here is also to file/cut the track end by maybe 1 or 2 millimeters at most, and place it back into the existing joiners. That will give it enough room for expansion later.

Update: A week later, the track was all straight again, the openings I made are all wide enough for all the track to fit in there, and the Stockton Yard panel shows no sign of warping anymore -- it now lays flat on the panel.

Initially I was wondering whether the issue could be to track metal expansion due to heat, or some kind of change on the part of the benchwork. I’m now tending towards the latter. I had never seen this issue before, yet given how the problem fixed itself, I’m going to guess it is not new. This is located in a basement, and we’re lucky that the temperature and humidity are generally constant pretty much all year around. We have had “weather” in this room before, including some flooding last year (about an inch of rain water in that exact spot, which got taken care of by the museum’s maintenance staff). A couple weeks before, we did have some hot weather so it’s possible the layout wood got dryer than usual for our customary oceanic foggy San Francisco weather. The benchwork there is the usual 1x4 lumber with something like ½ inch Homasote on top of it. The front panel that warped on the Stockton Yard panel looks like it’s made of some kind of fiber board.

Looking back at the previous entry, I realized we had some electrical shorts developing out of nowhere. I wonder whether they could be related. I should try to see if they “magically” fixed themselves in between.