The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

2022-10-31 - Randall Repairs: Turnout T111 (2nd fix)

Category RandallAffected |

Turnout T111 (after Fairfield station, arriving at Lodi). |

Description |

Specific steam engines stop-and-go on the turnout. |

Summary Fix |

Power the switch rail. |

Description of Issue

We’ve had some specific steam engines derail on Turnout T111 in the past. In the last repair attempt, it was identified the switch rails were loose because there is no turnout throw rod at all. Previously the point rails were spiked, then glued, and that addressed some of the issues for a while.

However most BLI steam engines still stop-and-go on that turnout. An annoying feature of the BLI engines is that they stop when they lose power (ok, that’s understandable) but then they speed up as soon as they cross the dead spot. When doing so, the engines typically have a jerking motion that either derails the steam engines complicated wheelsets, or derails the attached cars, or both.

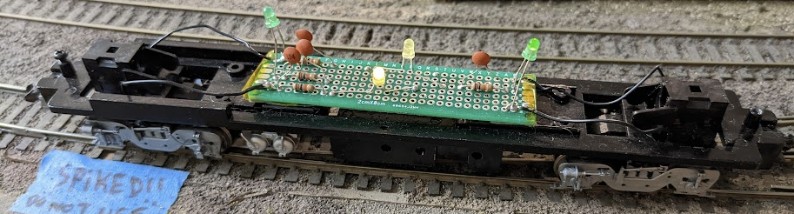

First order of business was probing the track with a multimeter, with the track power off. I was looking for a potential high resistance on the powered frog connection, and found nothing. With the track power back on, I carefully checked the track voltage, and then ran the Dead Spot Detection Car looking for dead spots. It was actually subtle yet I finally found one after many many attempts:

The rear (left) truck green LED is off. That means no power on that truck.

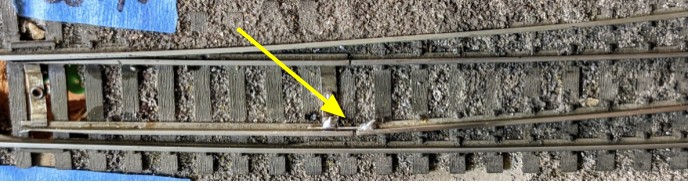

Looking at the turnout from above, what I found is that there is no power on the inner switch rail, even though there is power on the inner closure rail (the fixed one):

To be clear, I do not think this will positively and uniquely solve the problem. We have issues here with long base steam engines like the Challengers. There’s no way a 2-inch dead spot is the sole cause of their problem. Even my test engine of the day, a 2-8-0, is longer than this dead spot, yet it was stopping right there. So at the very least, we can fix this, and hopefully remove one issue even if it’s not the only one.

Description of Fix

This turnout is spiked because the inner switch rail is floating, and the outer switch rail is loose.

Ideally that turnout would be replaced. Unfortunately that's not something I know how to do on a heavily scenicked piece of track.

Rather than poorly fix a turnout we don’t use, I spiked it last time. Which also means I can take a few extra liberties that I would not do on a regular turnout.

Namely, we need power to that switch rail, and I know I have power in the fixed straight and curved closure rails. Thus the “easy” solution was to bridge them to power that switch rail and the switch rod, something like this:

Here the “liberty” I’m taking should be pretty obvious: I’m soldering on the inside of the rails. Normally that’s a big no-no since the wheel flanges need to go there. That’s why we always solder on the outside of the rails. But since this turnout is broken, we are never going to use the diverging route, and thus no wheel will get close to the curved closure rail. What I did is strip a little bit of wire and solder it on the fixed curved closure rail on one side, and on the switch rail & switch rod on the other side. That switch rail is the one that used to be loose so that it also attaches the switch rail to the rod properly, as well as powering it.

After that, I ran the little 2-8-0 steam engine a dozen or more times, at different speeds. It ran fine for pretty much all the runs except I still experienced one stop-and-go on the turnout. I wasn’t able to reproduce the issue more than once. So we know it’s not perfect, but it’s probably 90% better than before. I’ll take that as an improvement.

We also have a similar stop-and-go behavior of these BLI engines on the 2 next turnouts, although I carefully checked them out and they do have proper power on the rails.

Since I was working in this area, I took some time to also fix a minor issue on the turnout T110 nearby:

I had noticed the engines were “humping” when going on top of that frog. I carefully scraped the part between the frog and the closure rail, and it was full of that black soft material which you can see at the bottom of the image. That is typical Bright Boy material accumulated over the years. I’ve noticed the issue in several turnouts at the museum. Not only is the Bright Boy a very poor way to clean the rails, but it’s also very soft and gets stuck in turnouts and any other place where rails have sharp edges. I wished people would stop using that on the railroad.

Fix time: 1~2 hours.