The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

2023-01-20 - Randall Repairs: Block B321

Category RandallAffected |

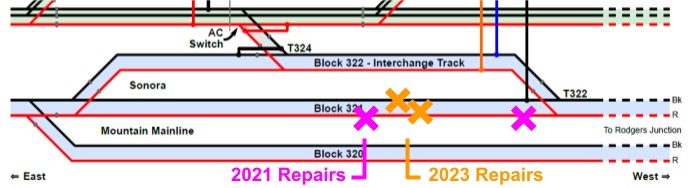

Mainline B321 close to Turnout T322. |

Description |

Dead spot on Mainline B321. |

Summary Fix |

Fix bad track joiner. |

Description of Issue

Recently we were back at having the automation freight train “hesitate” on block B321, and yesterday the passenger automation train totally stopped dead on that block:

We did a previous fix on the block B321, the issue was a broken solder join. On the track schematics, today’s repairs were performed in the same vicinity, but interestingly this time we had breaks on both rails:.

I tried to use the Dead Spot Detection car, and it correctly identified the dead part of the track, but the rail breaks themselves were quite subtle to see:

The breaks themselves were actually just that -- literally broken rails with I believe likely metal joints, but it’s really hard to tell. I could not detect any trace of solder on the metal joints:

Inner rail break.

Outer rail break.

Description of Fix

The fix was simply to apply fresh solder on what I believe is an old metal rail joint. I did not try to be fancy and bring any kind of expansion relief here. Part of it is that it’s really hard to reach that spot. To reach the inner rail, I literally had to climb on the fascia already and use a little mirror to work on the back of the rail.

The last step was to try this fix with the automation:

Fix time: ¾ hour.

Update 2023-02-05: Second Fix

The solder I did on the outer rail didn’t work for long: two weeks later, the automated train was dead on that spot again.

I removed as much solder I could out of the join, a used a little wire to bridge the two rails:

It took almost 2 hours to do that solder job. And I actually did it 2 or 3 times as I didn’t like the first ones.

It’s quite hard to work on that area because I literally have to climb on the fascia to access it, being careful not to damage anything in the mainline that loops twice in front at that spot. In the end, I managed to do this, which wasn’t too bad, even if not exactly subtle:

I do realize a better option would be to drill vertically on each side of the join and pass a feeder wire under the layout. That would make for a better visual solution. The other thing I have started doing is “paint” over these shiny solder joints using a black or gray marker. I’ll likely do that here. From a distance, they are then extremely hard to spot.

Fix time: 2 hours.