Presentation & Automation of the

Randall Museum Model Railroad

Last updated 2024-08, by Raphaël Moll

This document gives an overview of the model railroad located in the Randall Museum in San Francisco. It first describes the “original” state of the layout and then follows up with the technical details of the automation of the layout, as well as the on-going changes and maintenance. Disclaimer: A lot of the content in the first chapters is based on personal observations trying to decipher the existing layout and provide documentation where little or none exists, and as such are entirely based on my own discussions, observations and understanding -- and many times lack thereof. However, the sections on automation and maintenance are authoritative and are updated on a regular basis to reflect the current state of the layout.

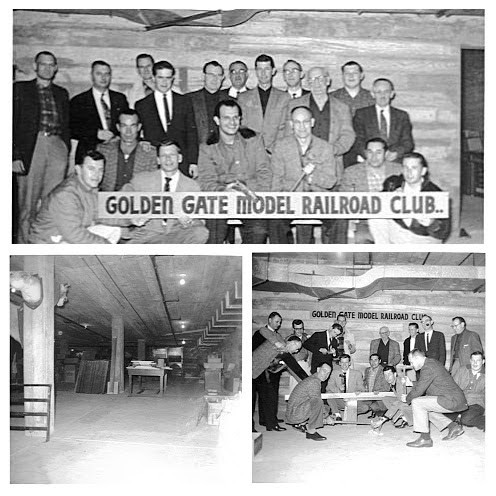

The model railroad was built by the GGMRC (the Golden Gate Model Railroad Club), starting in 1961. It is located in the basement of the Randall Museum in San Francisco, CA.

1.2- Model Railroad Design Impact

4.4- East-West, Running Direction, Polarity, and Common-Rail

5.2- Building Illumination / Lights Power Supplies

6.2- Block Power for Yard Panels

6.3- Front Yard toggles on Mountain and Valley Panel

6.4- Block Power Selection for Mainline Control Towers

6.5- Valley DC Power Selection

6.8- How Not to Wire a DCC Layout

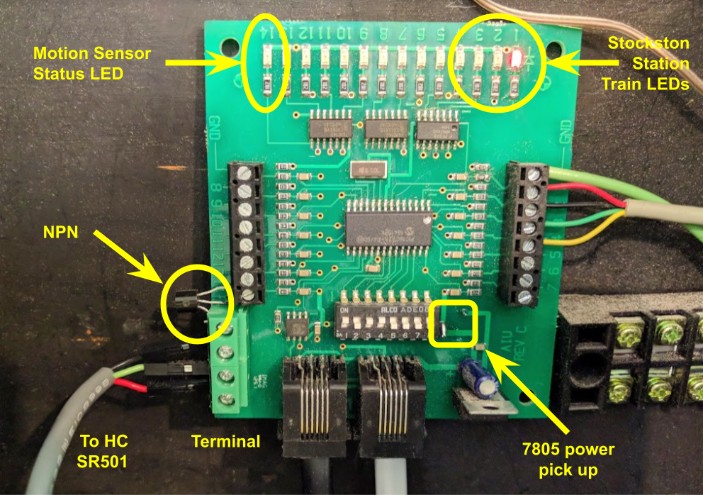

8- Stockton Station & Stockton Yard

9- Stockton Industrial Area & Dow Freight Sidings

10.2- Update to Block B905 & Turnout T110

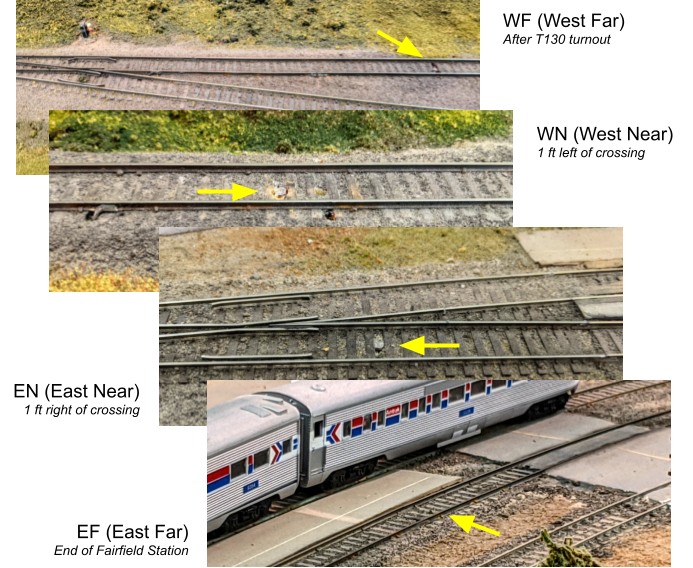

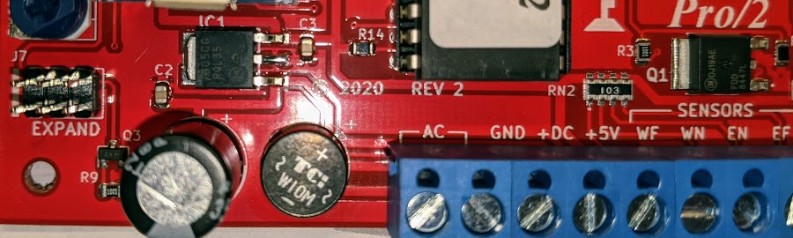

10.4- Fairfield Grade Crossing

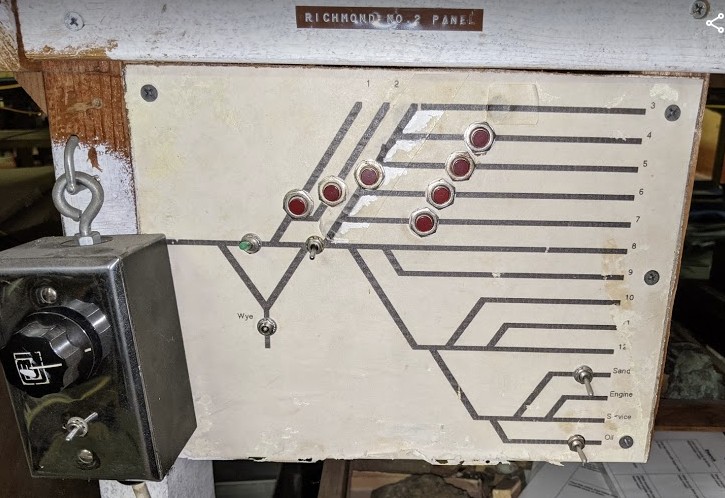

13.2- Richmond Industrial Yard

16- Changes from GGRMC to Randall

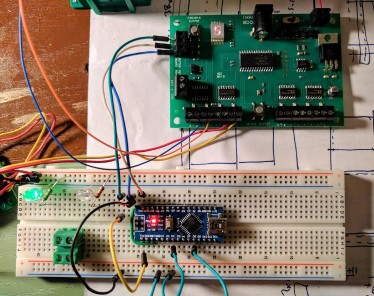

16.1- DCC Conversion for Automation

16.2- The Window Barrier and Fascia

17.1- Initial Automation Proposal (2016)

17.2- Revised Automation Proposal (2017)

17.3- Updated Automation Proposal (2018)

17.4- Further Automation Proposal

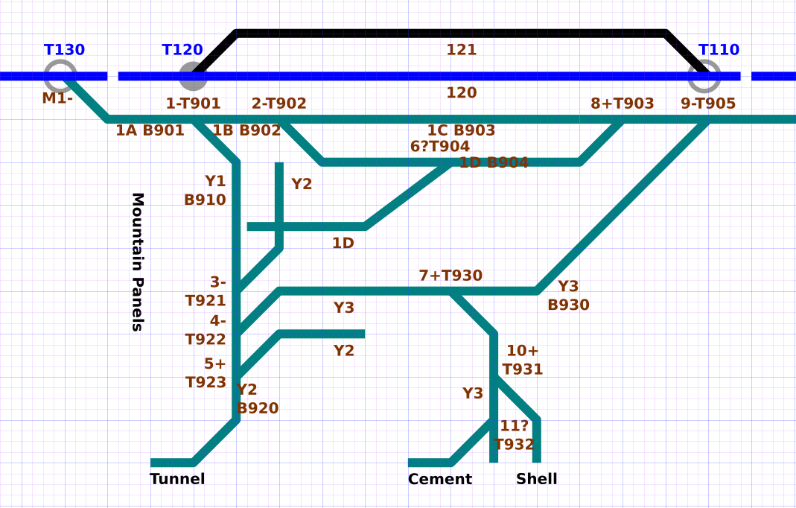

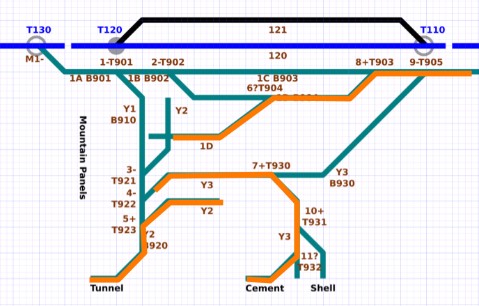

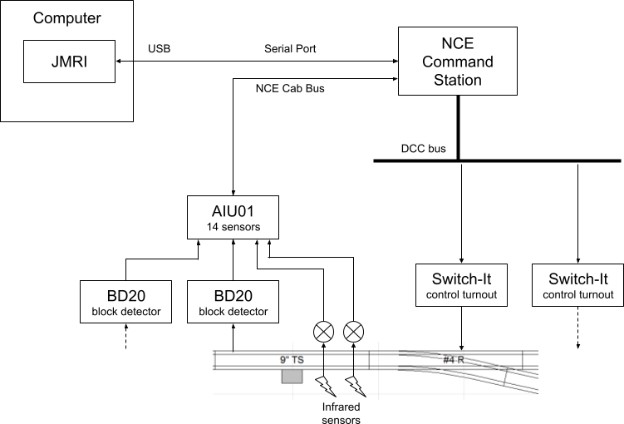

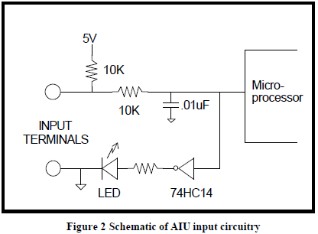

19.1.3- Mountain Panel 1 DCC Block Detection

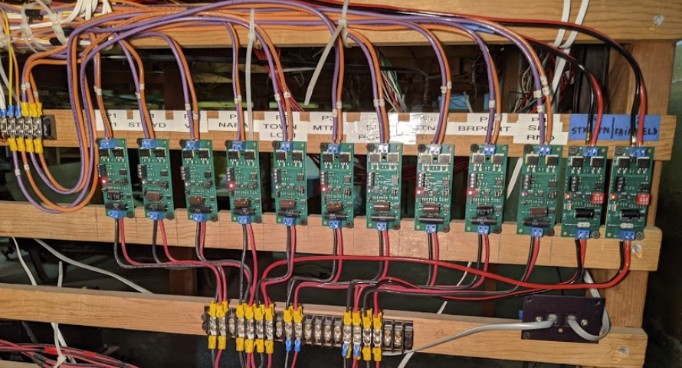

19.1.4- DCC Block Detection on Other Panels

19.2- Turnouts conversion to DCC control

19.2.1- Existing turnout implementation

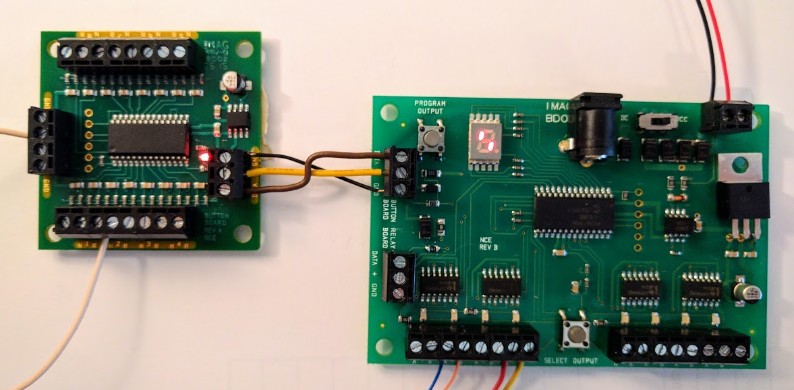

19.2.3- DCC implementation details

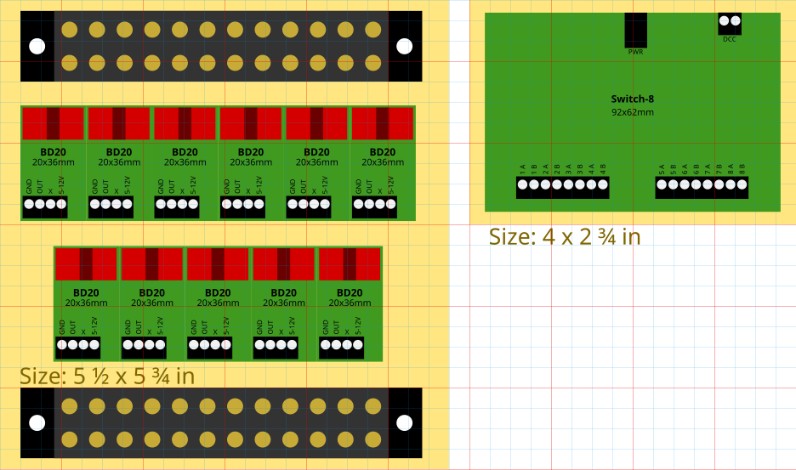

19.2.4- To convert a Turnout to DCC using NCE Switch-8

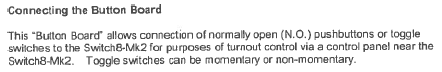

19.2.5- Somewhat Correcting the NCE Button Board

19.2.6- To convert a Turnout to DCC using Digitrax DS64

19.3- List of DCC Controlled Turnouts

19.4.1- Single Automation Toggle (2017)

19.4.2- Dual Automation Toggle (2018)

19.4.3- Update to Automation Toggle (Mid 2018)

19.5.1- Activation Buttons (2017)

19.5.2- Activation Buttons, Missed Events (2018)

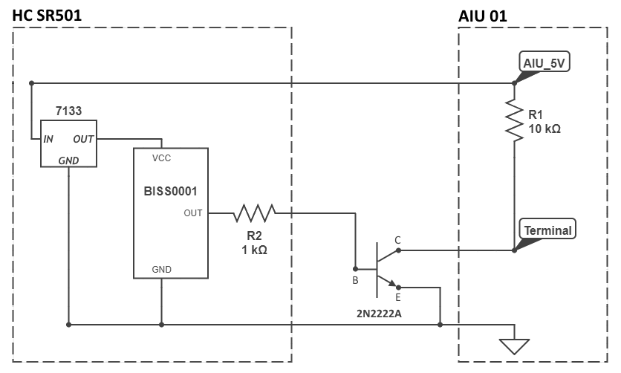

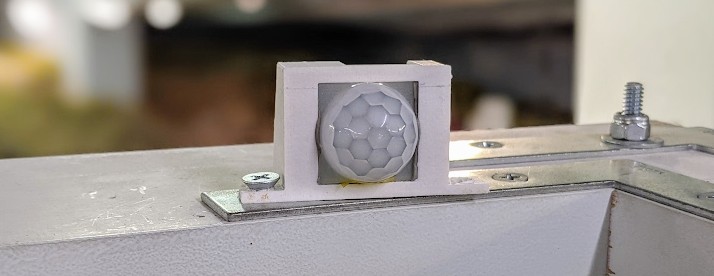

19.5.3- Motion Sensor (Mid 2018)

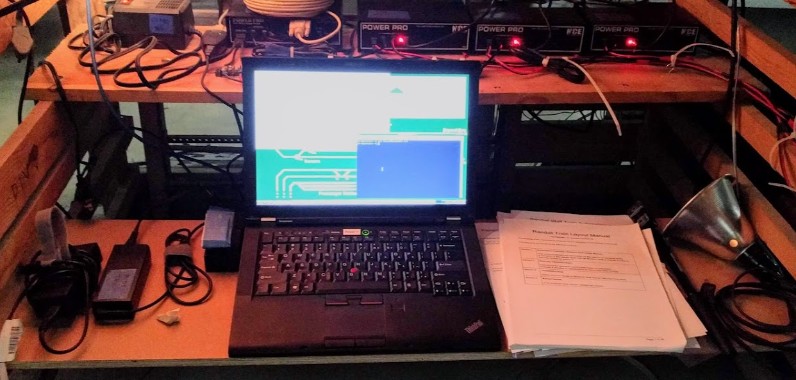

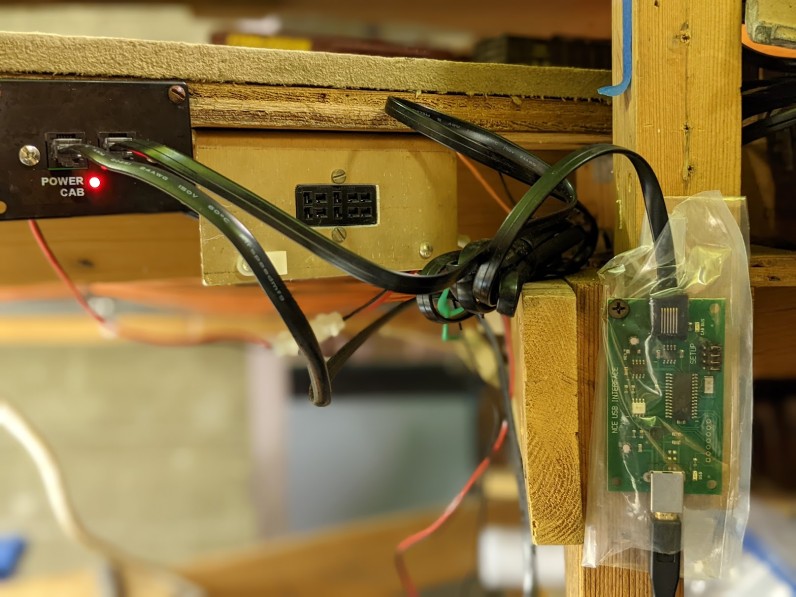

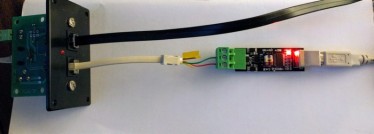

19.6- Computers & Infrastructure

20.2- Phase Exploration (2017)

20.5- Follow-up Maintenance and Work (2018)

20.6- Follow-up Maintenance and Work (2019)

20.7- Follow-up Maintenance and Work (2020)

21.2- Phase Exploration (2017)

23- Ongoing and Future Projects

23.0- Pending Work on the Layout

23.2- Project: More Labels & Documentation for Operators and Visitors

23.2.1- Labels & Documentation for Visitors

23.2.2- Labels & Documentation for Operators

23.3- Project: Power for the Branchline

23.4- Project: More Blocks & Turnout Control for Branchline

23.5- Project: Power for Stockton Passenger Station [done]

23.6- Project: Turnout Control for Stockton Passenger Station

23.7- Project: Block Detection for Stockton Passenger Station

23.8- Project: Power for Fairfield

23.9- Project: Automation for Fairfield

23.10- Project: Fix Mountain Panel Toggle Panel

23.13- Project: Mountain Panel

23.15- Project: Access to Richmond / Napa from Mountain [done]

23.16- Project: NCE AIU01 to Monitor EB1 Circuit Breakers

23.17- Project: Update Building Lights to LEDs

23.18- Project: Workbench with NCE PowerCab, Digitrax PR3, LokProgrammer

1- Model Railroad Design

1.1- Overview

The design of this model railroad may look peculiar and confusing to first time observers, with trains going into tunnels and emerging somewhere else in the opposite direction.

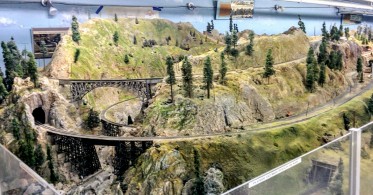

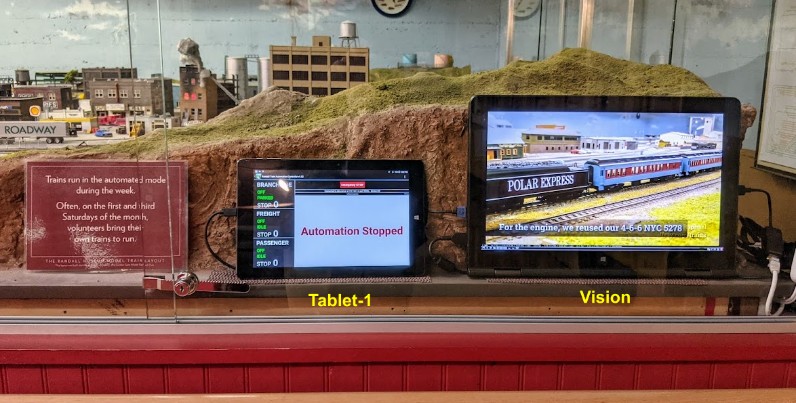

Here’s what visitors see when they enter the room:

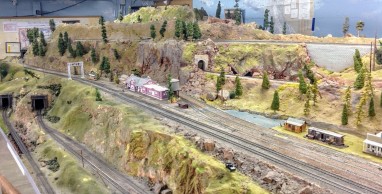

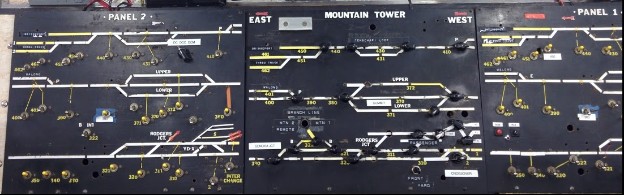

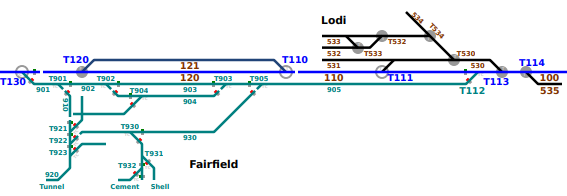

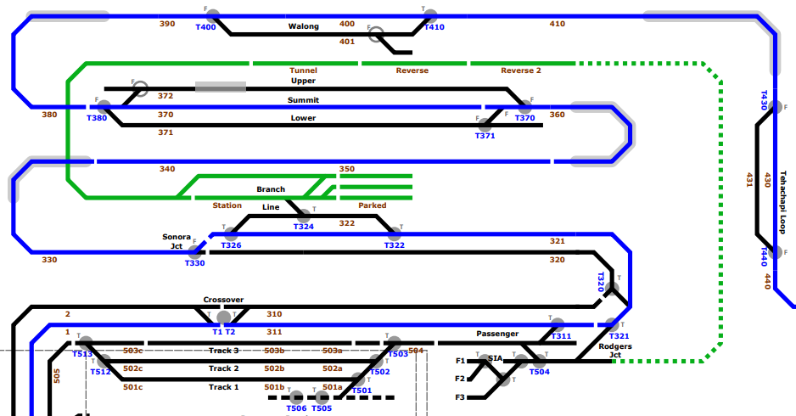

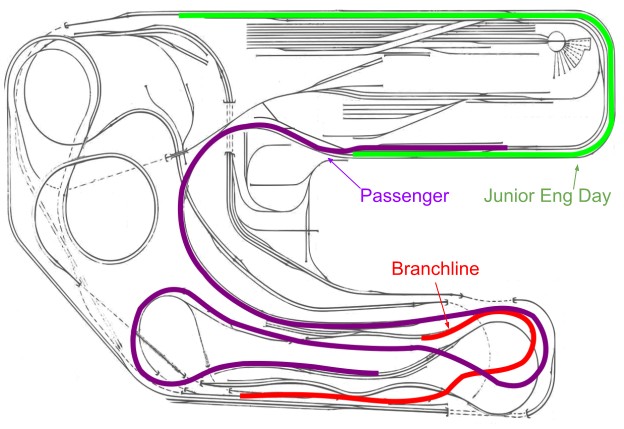

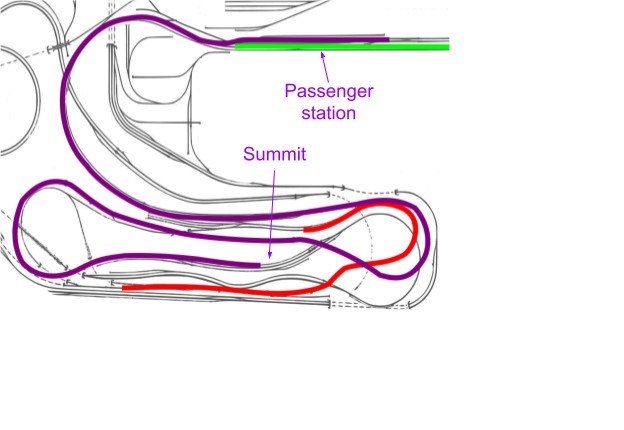

And here is the track plan, which shows the multi-level mainline looping over itself repeatedly:

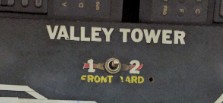

The track forms a mainline, which is sometimes a single track and sometimes a double track. There is a branch line and several yards. As it was common in this era, the layout is controlled by two main control "towers" -- the Valley Tower and the Mountain Tower. These panels concentrate all the blocks and turnouts controls for the corresponding sections of the layout. Each yard has its dedicated block and turnout control panel.

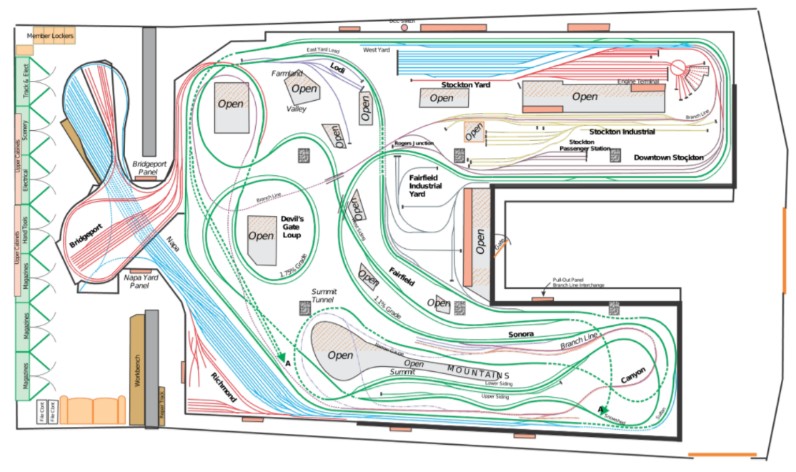

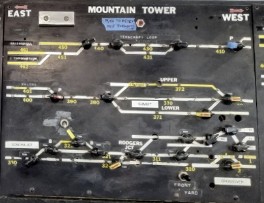

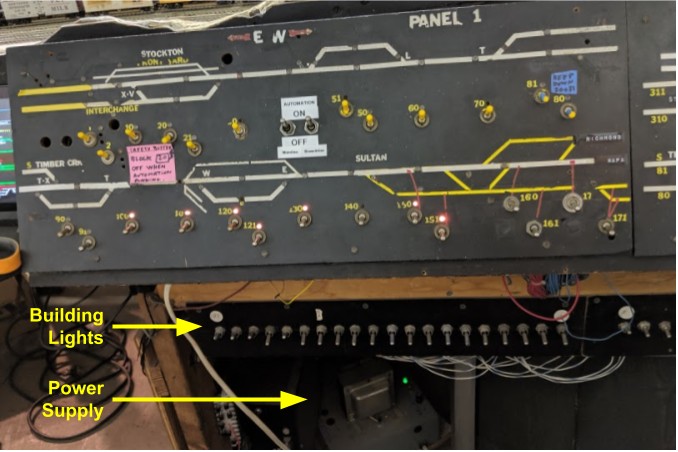

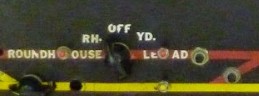

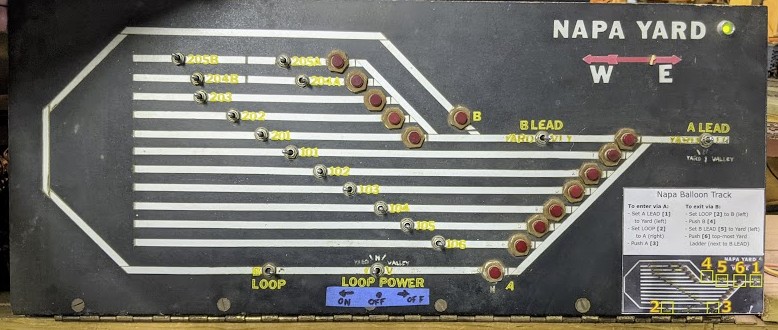

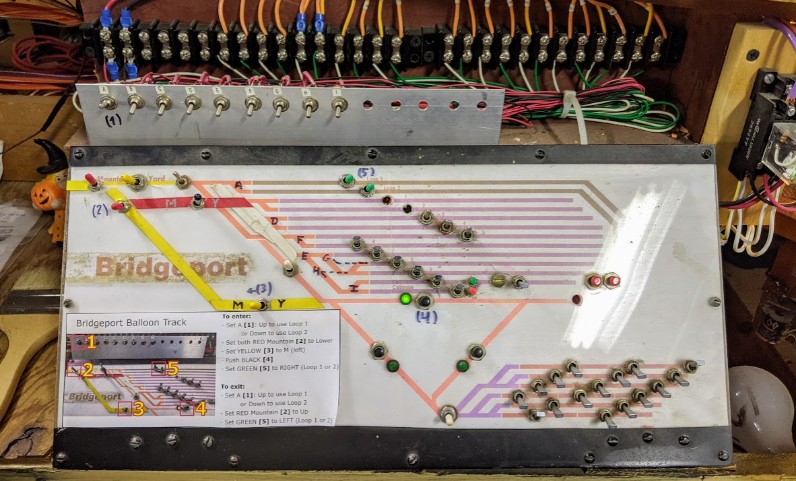

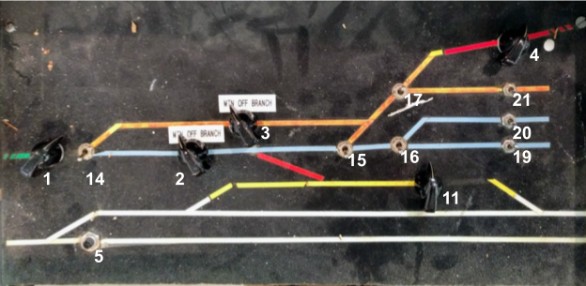

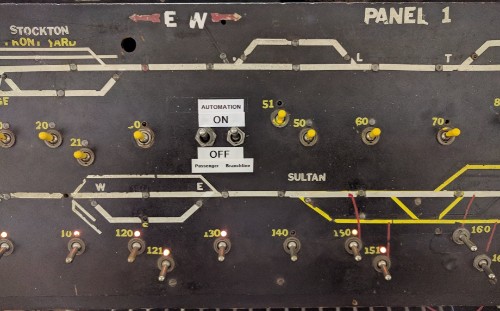

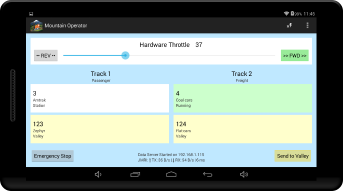

Operators are usually very confused at first. Here’s what one of the two main control panels looks like:

The Mountain Tower panels (block control and turnout control)

Although it all seems confusing, there is some definite logic and rationale in the layout plan and the control panels.

There are two major power districts (valley or mountain) which can be operated using two different throttles (power supplies at different levels). Each "tower" (mountain or valley) is actually composed of three sub panels, as pictured above: one turnout panel and two block control panels (Valley 1 vs 2, Mountain 1 vs 2) which duplicate each block control, thus allowing a specific block to be powered either by throttles from side 1 or side 2 or turned off. At some points mainline blocks also had occupancy lights.

The yards have their independent throttles and tracks leads in and out of the yard have a power selector to dictate which throttle is powering an engine entering or leaving a yard. Later radio-controlled DC boosters and MRC power supplies were added.

This always seems confusing to the non-initiated so I’d like to introduce a bit of background on why the layout was built that way.

Layout design has naturally evolved over the years. This layout is built using what was the “state of the art” back in the 60s. The natural tendencies for layouts back then was to try to cram the most track in a given space. A longer mainline makes people who like to run happy. The easiest way to achieve that is to have multiple levels, with the track looping on itself.

In the pictures above, the “mountain” area and the “devil gate loop” are good examples of that. On the mountain side the track goes up through three levels, on the other side it goes down through two loops. This looks visually confusing as trains enter a tunnel at the middle of the mountain at one level and go out of the mountain at another elevation in the reverse direction. As an anecdote, it is worth noting that this design style fell out of favor in the 80s in favor of more linear layouts with elevation being taken care of using helixes behind the scene -- which has brought different design issues.

One interesting design consideration is that when I joined the GGMRC in 2014, everyone was running the mainline clockwise, that is starting from the Stockton Yard towards the Stockton Station then to the Mountain/Summit then going down through the “devil’s gate” loop (which is obviously build to look like the well-known Tehachapi Loop in California). However I was told the layout was originally designed to run counter-clockwise and the reason they choose to run clockwise is that the mountain is a 1.1% grade going up followed by the loop with a 1.75% grade going down, which is much easier than the reverse. Personally from an operational perspective I see the layout as being able to run both directions at once with clear sidings for meets and potential for helper units being added and removed for the long grades.

Let’s consider the electrical and control aspect. The layout obviously started as DC (non digital) control. One bit of background explanation is useful here: on a DC layout, the trains are powered by the voltage applied to the track. Typically one transformer is connected to the track and varying the voltage controls the trains speed -- all trains powered by the same transformer all go at the same speed at the same time, they cannot be individually controlled. This is clearly an issue on a large layout like this where there would be multiple trains running at the same time, possibly in reverse direction.

To solve that issue, the mainline is cut into blocks that can be independently turned on or off. One additional complexity added here is that they have not one but four independent power sources -- two power districts (the two Towers) which each have two “cab throttles”. On the Mountain Tower picture above, the “Panel 1” on the right and the “Panel 2” on the left can be used to decide if a given block is powered by the throttle 1 or the throttle 2 or neither.

Yards have their own control panels with their own separate “cab throttle” power supply. A switch is used to decide whether the yards are powered from throttle 1 or 2 (to enter and leave the yard) or by the yard throttle (when inside the yard).

Thus two operators could run trains on the Mountain area, with two different operators on the Valley area, then each yard could have its own operator.

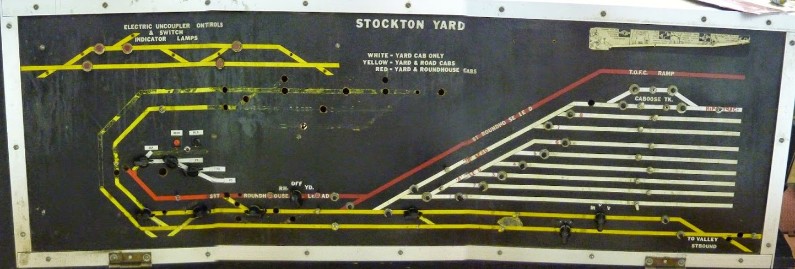

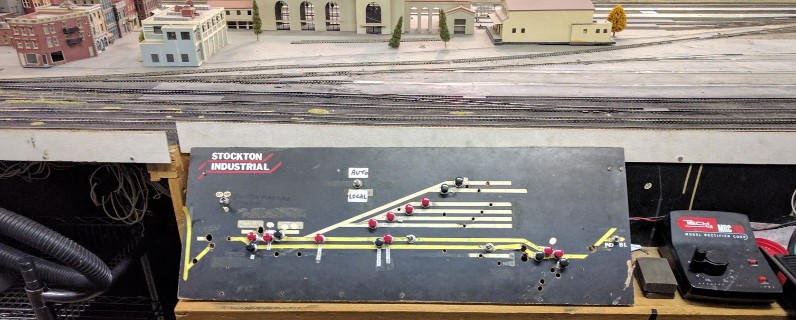

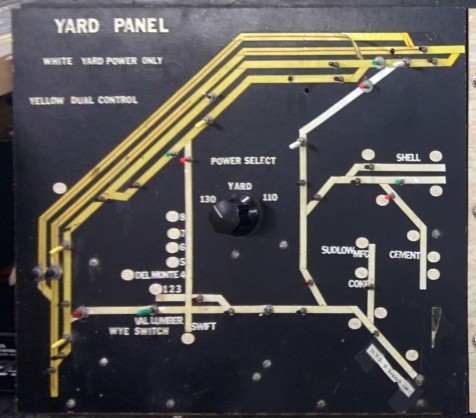

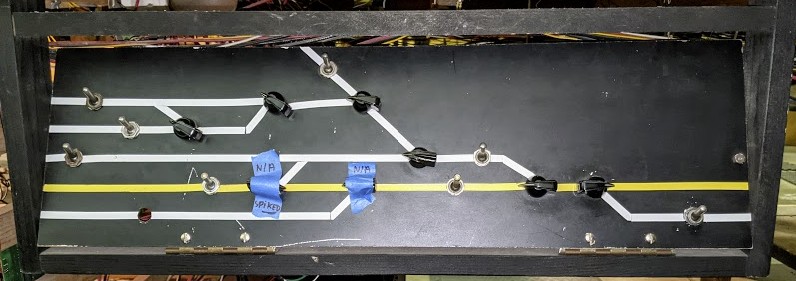

The Stockton Yard panel (apologies for the low quality stitching)

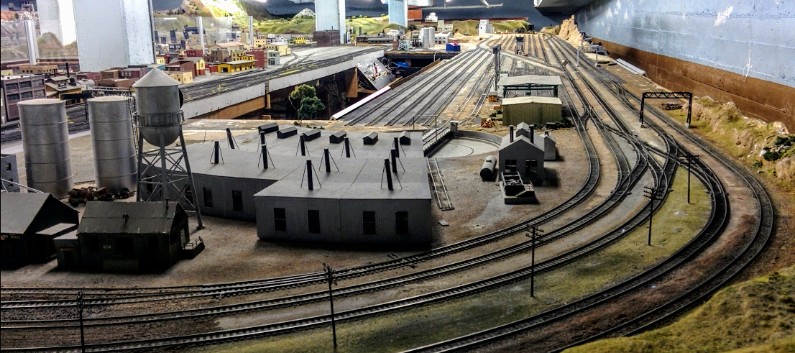

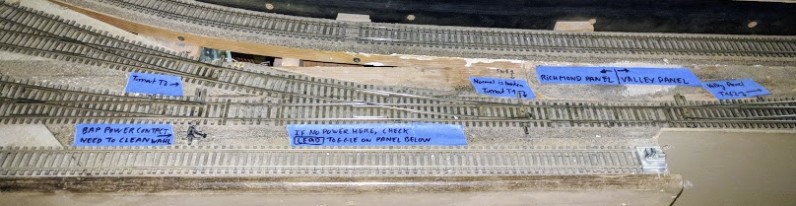

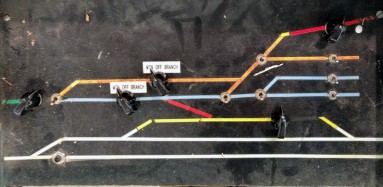

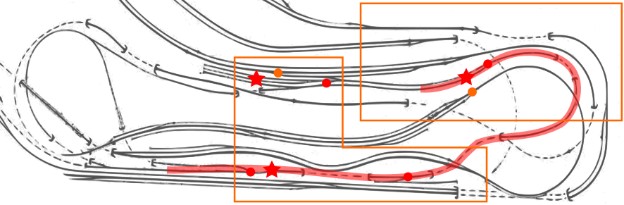

To understand the nature of the confusion in operating this, let’s look at this picture:

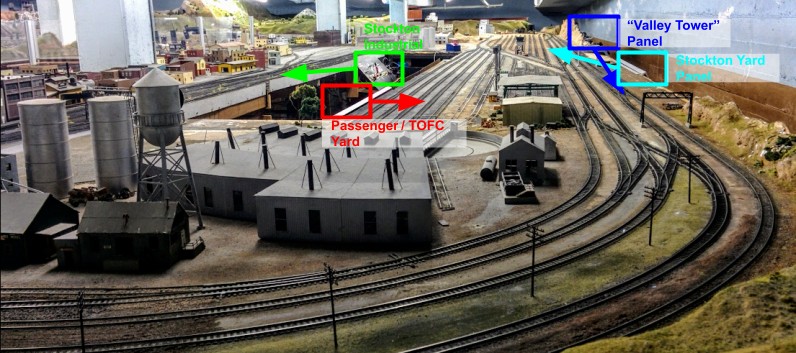

This part of the layout is actually controlled by 4 distinct control panels, each located at different places. Here’s the same image with indications of where the control panels are and which area they operate:

The mainline is on the very right, controlled by a “valley tower” control panel in the middle behind that mountain on the side of the layout (dark blue); the main Stockton yard is composed of two sections controlled by two separate panels (light blue and red) and the Stockton Industrial yard is controlled by another panel (green). One needs to crawl under the layout to reach the two yard panels denoted in green and red below.

Another issue worth pointing out is that the “Valley Tower” control panel, denoted in dark blue above, also controls mainline turnouts which are located on the very opposite side of the layout, out of visual range.

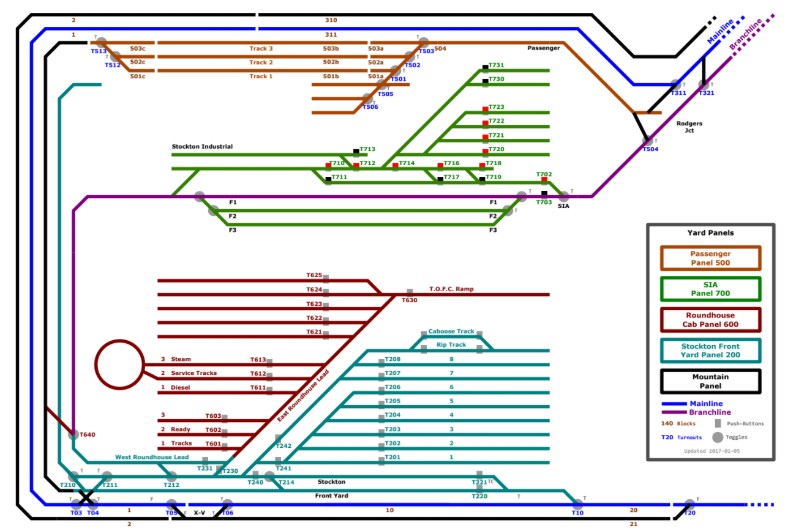

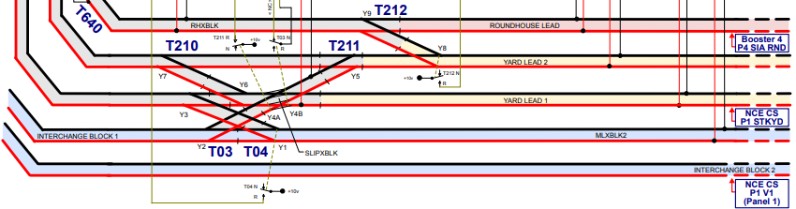

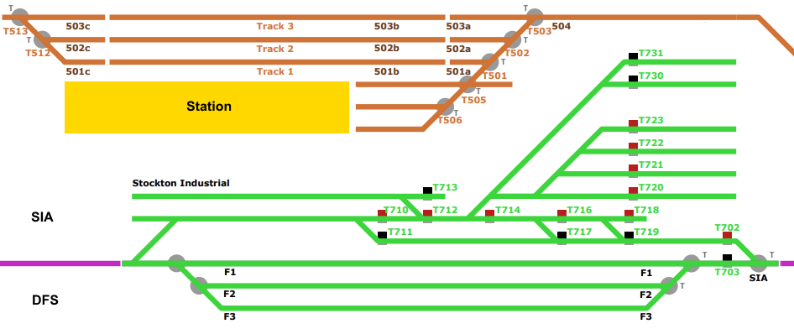

The following schema represents the track from the picture above (seen from the left). It shows which track is controlled by which yard panel:

One leading confusion is that the panels are old and quite frankly poorly documented. The schema above was made to understand the logic behind it and especially to understand what happens at the boundaries.

Of note, the DFS is incorrected mixed with the SIA on this drawing as I did not understand the difference between both at the time. This topic is further addressed in the DFS/SIA section below.

It is worth noting that although the panels have blocks numbers, these have no matching visible indication on the layout. Similarly, turnout toggles offer no way for one to directly match a specific button to a turnout on the layout. The only link is the track plan on the panel, which some people find obvious and others find cryptic.

1.2- Model Railroad Design Impact

From an engineering and operational perspective, this is quite a good scheme. There is both logic and complexity. For example, taking a train from the mainline to the passenger yard next to the roundhouse involves no less than three panels, located at different places. That’s a lot of operational potential and also a lot of busy work. The downside is that it involves quite a bit of crawling under the layout to reach some of these panels. It has been observed that most club members did not care for that complexity, which means few would look for such operations or be extremely reluctant (and annoyed) at it.

The same goes for running in opposite directions on the single-track mainline. On the prototype (“real”) railroad, it involved careful coordination (typically with timetables and hand-delivered orders) to have trains that can meet and stop at sidings. The same would be needed here, with operators coordinating with each other and using the sidings available via the Mountain Tower control panel or the Valley Tower control panel. The lack of labelling and the lack of easily identifying which turnout toggle controls which physical turnout means that a lot of operators would just randomly flip a toggle to see if they actually triggered the turnout they wanted. We have seen every operator make mistakes when switching, including seasoned operators. This is not a sound operating principle.

Consequently what most members did was just stick their trains on the mainline and run it as a unidirectional loop with no operational variety whatsoever. Everybody’s running long trains one following each other.

Another issue is that this layout was also an “exhibit” for the museum hosting it. Every Saturday, visitors would come in and expect to see trains running, most visitors being kids who want to see trains running around, which works well on this complex looping layout design. This compounds the issue as operations are not something exciting to look at and falls in disfavor of simply running trains on the mainline as a continuous loop. On the plus side, since the layout loops over itself, even multiple trains all running in the same “logical” direction look like they are going in different directions visually so it does give a greater sense of variety than there actually is.

Historical anecdote: this kind of layout is well designed to have one manned dispatcher in each control tower. Two operators can run on the mainline in reverse of each other and coordinate meets with the tower dispatcher. Since each operator would use the wired “throttle” connected to the tower, they would be next to each other and be aware of the area in control. Eventually starting in the 70s/80s, this layout design started to fall in favor of “walk around” cab designs in which small control panels are scattered on the fascia of the layout, directly facing the turnouts they control. This makes it trivial to understand which toggle controls which turnout. Plug-in throttle or wireless systems mean an operator can literally walk around the layout following its train, instead of relying on a central dispatcher. A walk-around design also greatly simplifies electrical wiring as there is no longer a need to run long cables from a central tower to remote parts of the layout.

As indicated above, current practice is to have trains run in a loop in a clockwise running direction -- from right to left when looking at the mainline for example in front of the Stockton Passenger Station. West would be on the right, with trains running towards East, on the left. Allegedly the layout was built for running in the reverse direction (from East to West) and this practice changed later to make the grade in the “Devil’s Gate / Tehachapi loop” easier as the grade is fairly steep uphill. (One would argue that maybe the original intent was to mirror the prototype and thus force operators to use helper engines, providing more operational variety, whereas the current setup results from a desire for erasing any kind of operation and just run the layout as a naive mainline loop, but that’s not a discussion for this document.)

2- A Brief History

This is a work in progress. Some events are approximate -- all dates that appear here are based on some kind of visual evidence (some panel’s inscription, older picture, older document) or blog post.

1961: The GGMRC (the Golden Gate Model Railroad Club) starts the layout in the then unused Josephine Randall museum basement.

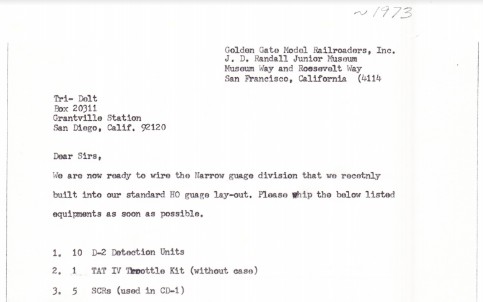

1967: Design documents for Branchline referencing a 1967 “Transistor Throttle” from Tri-Delt.

1990-91: Branchline is upgraded or modified with new panels.

2000(?): Some members vote for/against an early DCC conversion.

2009: DFS tracks added to the SIA.

2013: DCC added.

2014: Museum announces to the GGMRC they need to destroy their layout. Hilarity ensues.

2015: Museum forcing a renegotiation of lease contract, ends up on impasse due to inflexible one-sided demands. Layout maintenance by long-time members is mostly inexistent.

2015, December: After months of painful and pointless negotiations, the remaining GGMRC members give up and officially donate the layout to the museum. The actual GGMRC association (GGMRA) is neither officially dissolved nor active after that.

2016: Randall Museum under renovation, and stated to reopen “early 2017”. No access to the train room is possible for most of the year. Two members propose a compromise to move forward, with yours truly to carry the work of maintaining the layout and at the same time propose some automation as the museum wants it.

2017: Randall Museum still under renovation. Limited access to the train room is possible. Automation starts to take shape using the RTAC software.

2018: Randall Museum reopens in February with a working, automated “train exhibit”.

2019: Ongoing repairs to support Saturday runs, rehabilitation of the train yards; automation gains a reputation for being solid and reliable.

2020: Randall Museum closed for COVID-19 Lockdown in March.

2021: Randall Museum reopens in October. Saturday running, yards, and automated trains are fully operational due to diligent ongoing maintenance.

2022: The GGMRA (a.k.a. GGMRC association) is allegedly officially dissolved.

2023: RTAC software version 2 is deployed.

A collage of photographs found in archives, labeled 1961.

Narrow-gauge Branchline is “ready to wire” in 1973.

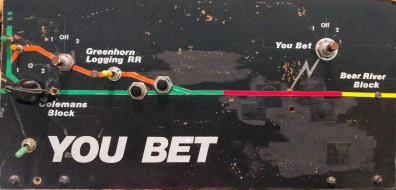

The Branchline You Bet panel, with inscription “Mike O’Brien 1990”.

3- Glossary

This is a glossary of terms used in the Manual for the Randall Museum Staff to explain what is known as the “Randall Train Room” -- these terms are referenced in this staff-specific documentation as well as on labels in the train room. The names are kept voluntarily non-technical (where possible and appropriate) in order to be as easy to understand by the staff as possible. As such, they may differ from what a model railroad technically-oriented enthousiast may expect.

Name / Label |

Pictures / Description |

|

Train Automation |

Computer program that automatically moves the trains on a timer during museum hours, based on detecting visitors' motion. It turns off automatically at 4:50 pm. |

|

Train Layout |

In Model Railroading terminology, a “layout” denotes the whole thing -- the miniature decor, the tracks, the trains, etc. |

|

Pullman Car |

Exhibit with the locked cabinet covering the lights and layout & outlet power switches. |

|

“Layout & Outlet” Power (main switches) |

The main switches at the entrance. The “Layout & Outlet” Power must be the first on and always the last off. |

|

DCC Power Switch |

The DCC Power Switch is located under the layout, next to the Automation Computer. It is located in a gray box protected by a gray cover. |

|

Auxiliary Power Supply |

A power supply located to the right of the Automation Computer. |

|

Automation Computer |

The computer under the layout, next to the DCC Power Switch. It runs a custom-made program that orchestrates the whole train automation. |

|

Name / Label |

Pictures / Description |

|

DCC Command Station |

An electrical device that provides power to the trains. It is located behind the Automation Computer. |

|

Valley Panel 1 |

The large black console with toggles to the right of the Automation Computer. |

|

Automation On/Off Toggles |

The two toggles that enable/disable automation, located on the “Valley Panel”. |

|

Mainline |

The main track where the Passenger and the Freight train runs. They share the track so only one can run at the same time. |

|

Branchline |

The track where the 2-car silver train runs. |

|

Passenger Train (runs on mainline) |

Currently that’s the yellow train. Color may vary as we change cars/engines. Parked next to the station. |

|

Freight Train (runs on mainline) |

The one next to the yellow train. Composition may vary over time. Parked next to the station. |

|

Branchline Train |

The 2-car silver train running on the branchline, by the mountain side. Train may vary with time. |

Name / Label |

Pictures / Description |

|

Mountain Side |

The right side of the layout with hills and slopes. It depicts California's Sierras. |

|

Valley Side |

The left side of the layout that is mostly flat, and contains the large city with a station and the building on fire. It depicts California’s Central Valley. |

|

Stockton Station |

The main large station located on the left side of the layout. The two Mainline trains (Passenger & Freight trains) are normally parked in front of it. |

|

Video Computer |

Located by the entrance, it displays a loop of videos of model trains filmed on this layout. |

|

“Engine” vs “Car” |

Different parts composing a train. Typically the “engine” is the first part (with the motive power), and “cars” are the ones behind. |

|

4- Electrical Design

“It seems to run on some form of electricity.”

4.1- DC, DCC and DCM

As stated above, the layout did start as a DC layout. Also called “analog”, in “direct current” mode trains are powered via the track and the voltage applied to the track directly dictates how fast the train motors go. Any engine placed on the same piece of track receives the power and thus runs.

Since the 2000s’ and 2010s’, trains layouts have started switching or being built exclusively for DCC, “digital command control”. In this scheme, model trains are still powered by the track and the track is always at full voltage. However each engine is equipped with a microcontroller (called a “decoder”). Each engine is given a number and the microcontroller listens for digital commands sent via the track and only accepts the ones for that specific number. Users operate the trains by using wired or wireless remotes (called “cab throttles”) which send run commands to a specific engine number.

A few years ago the layout was converted from DC to DCC. I could not find any specific documentation on the technical implementation of such, so the following is entirely based on my own discussions, observations and understanding -- and many times lack thereof.

The layout was not just “converted to DCC”, it was made to be able to work either in DC, DCC or “DCM”: each control tower has a large switch to dictate which electrical mode can be used.

DCM is short for “DCMaster”, an obsolete vendor-specific technology from Broadway Limited to address sound engines running on DC analog track.

From what was gathered, there was a rationale to keep the layout operating in both DC and DCC modes. First current members probably had a lot of DC engines which were not DCC compatible (it’s expensive and not trivial to convert a DC engine to DCC). There also seems that there was a split in the group between those in favor or against this evolution. Finally the “Junior Engineering Day” event (in which the club invites all museum visitors to run the trains) was only set up to work in DC as the engines used were not compatible with DCC.

From my point of view, the conversion was cleverly done and really well executed. Yet it does result in panels which end up more complicated than needed. The procedure to change the layout between DC and DCC mode was quite complex and error prone, involving changing toggles on both control tower panels and switching a number of power supplies. The procedure was not written down anywhere and only a couple members really knew what to do.

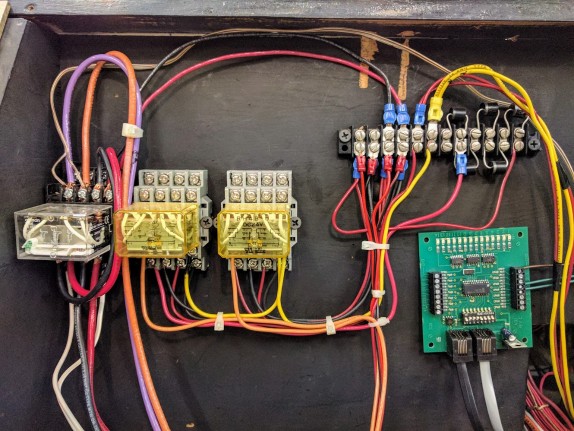

What’s behind these ‘DC / DCC / DCM” selectors… 3 relays and a lot of complicated power routing,

all that for a feature we never use and which is not even connected anymore.

Several key people wished the existing control panels stayed as-is, because of the nostalgia and historical significance. The problem is that this complexity has a cost. There has been a lot of iterative work on this layout over its fifty years of existence. There is a lot of obsolete wiring under the layout, it’s extremely hard to figure out if a given thing is actually used or not. The panels have the same issue. They have seen multiple iterations, with empty holes that used to host toggles doing who knows what. There are a lot of lights and wires for a former block occupancy system that is nowhere to be found. There have been additions hastily crammed in a corner in order to not change the rest of the panels. The list goes on.

4.2- Existing Wiring

Note: I’ll shortly describe the existing wiring of this layout here. This is not exhaustive. I also want to emphasize upfront that this is absolutely not a good model to follow for DCC wiring. I expand on the wiring in section 6- DCC Bus Wiring below.

There is a lot of wiring under that layout. A lot of it. A lot more than one would imagine.

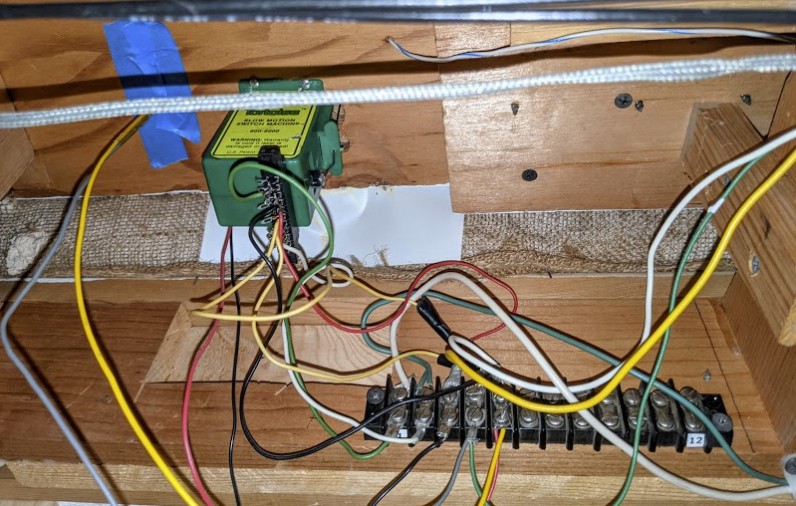

Some of that wiring obviously dates from the original DC design. The current wiring is a mixed bag. In some places it’s very clean and logical, on others it’s frankly just a big mess, with some remnants of wiring that goes unused. Then on top of that was layered all the DCC work and a bunch of more modern relay work, which although clean and logical adds one more layer of complexity.

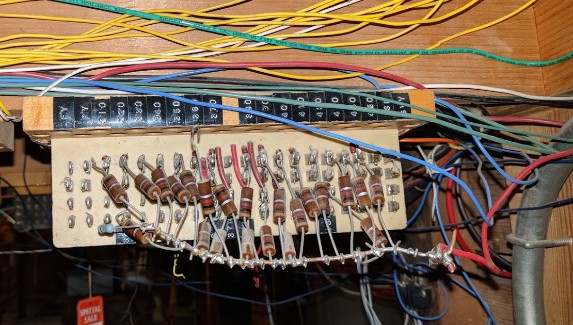

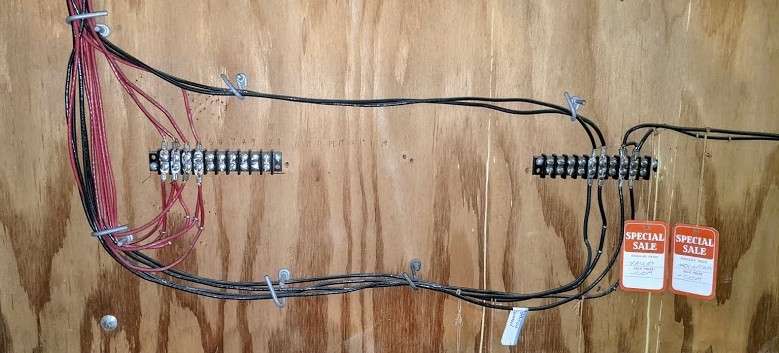

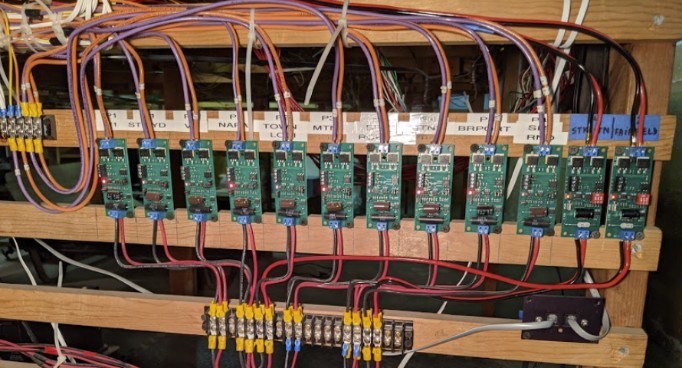

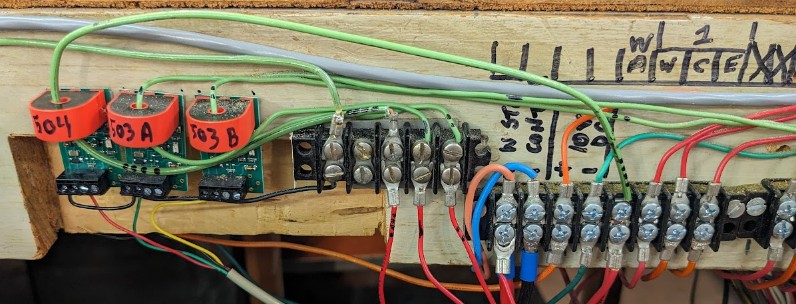

Here’s an example of wiring under the layout. The next picture shows the block power leads out of the Mountain Panel. A bundle of red wires come from the panels, and another bundle of red wires goes to power the blocks on the mountain:

Here’s the back of the interconnection board. The resistors are bias resistors from Twin T detectors (see note below):

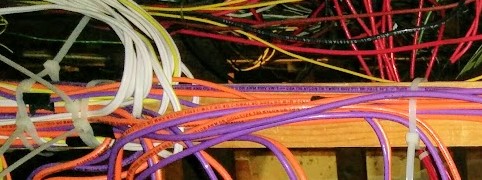

Speaking of bundles of wires:

On the left above is one of these bundles of red wires from that interconnection board above. It just wraps around and has been cut. The whole interconnect board is such a mess that I’m afraid of even trying to remove these obviously unused wires. Next picture shows the bundles of black wires. These were traced going all the way to the back room of the layout -- we’re talking 40-50 feet away, then connect to a bundle of purple wires which go back in the reverse direction -- along the bundle of black wires for a while, except from time to time they split off and end up connecting to some red wires (but not the ones from above). As explained to me by Mr. Perry, all these things -- the bias resistors and the extra bundles of wires -- are remnants of an old system of block detectors when the layout was wired exclusively in DC and no longer serve any purpose with the layout in DCC.

4.3- Plans

Two sets of plans were found, ones that look like “historical” original ones, and a later set from Mr. Perry from 2000/2007.

I have no idea how relevant the original plans/schematics are with regards to the current state of the layout. These were scanned (TBD: and should be posted in some fashion here after clean up).

The ones from Mr. Perry seemed quite relevant, and they describe a bunch of relays doing active power routing around some of the complex track intersections and interexchange tracks back from 2000~2009 when the layout was still running in DC. All the equipment is still intact on the layout. Mr. Perry’s DXF schematics were reconstructed as SVG and PDF here:

Randall Schemas - SD+DOW - 2018-11-11.pdf

(TBD add Branchline interchange schema as PDF… currently shown in 15.2- Branchline Main Panel)

4.4- East-West, Running Direction, Polarity, and Common-Rail

East-West

- On the Mountain Panel, East-West to left-to-right:

- [Left] East < Summit < Sonora < Stockton < West [Right]

- On the Valley Panel, East-West to left-to-right:

- [Left] East < Stockton Yard < Timber Creek < Sultan [Right]

- When looking at the Stockton Station from the public area: East is Left, West is Right.

- However when reading the Stockton Passenger Station schematics from Mr Perry:

- Approach West is to the left, and Approach East is to the right.

- The passenger tracks are split into West | Center | East from left-to-right.

- This is reversed to every other panel on the layout.

There are actually two conventions on the layout:

- Both original Mountain Panels and Valley Panels have labels “ ⇐ East | West ⇒ “.

- The schematics for the Stockton Passenger station, redone in 2000, use the reverse direction.

I am going to adhere to the original direction as it makes more sense, the one on the two main older panels. For example running from the town of Stockton, CA towards Sonora, CA is a West-to-East travel direction. This logically puts the Summit / Cajon Pass and the Tehachapi Loop to the East of Stockton to match their geographical counterparts.

The “East / West” and “E / W” signs are clearly visible at the top of the Mountain and Valley panels.

Running Direction

Allegedly, the apocryphal story is that the layout was designed to run in a East-to-West (left-to-right, counterclockwise) direction but in the 2000s the main running direction changed from West-to-East (clockwise) because it provides smaller gradient slopes. And indeed the grade on the Devil’s Gate Loup / Tehachapi Loop is fairly steep and the current running direction makes that a downgrade.

This would explain the electrical wiring design with the common rail is the left one in a left-to-right running direction, and that logically puts the “red” rail on the right side, which is a common practice (“Red is Right Rail” being a mnemonic that I’m used to, as used in DCC decoders wiring). See schema below.

Common-Rail

This is a common-rail layout design with power districts.

One would expect the power district boundaries to be double gapped and the block boundaries to be single gapped.

In the original direction of running from East to West (Left to Right in front of Stockton Station):

- Red is Right Rail -- the outside rail (front-most to the public) is the “red” rail.

- Common is Left Rail -- the inside rail (far-most from the public) is the “common” rail.

In the current direction of running from West to East (Right to Left in front of Stockton Station):

- Red is Left Rail -- The outside rail (front-most to the public) is the “red” rail.

- Common is Right Rail -- The inside rail (far-most from the public) is the “common” rail.

The branchline should match the polarity of the mainline at Angels Camp and the inversion should happen just east of RJ6 (the Branchline/DFS/SIA side of T321). The latter is not necessarily the case due to the way the LK100 is hooked on the branchline power bus.

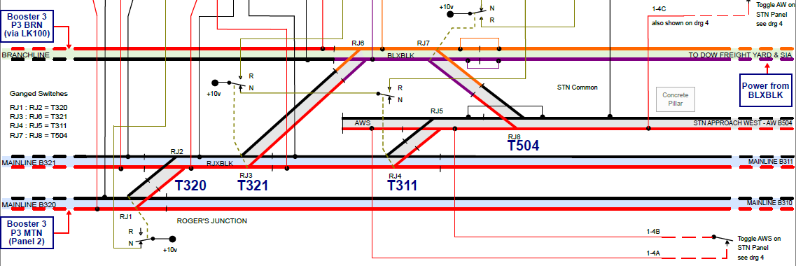

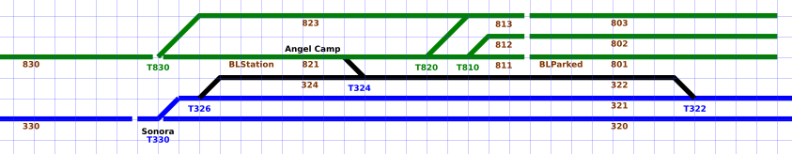

Track polarity where Branchline meets Mainline at Rodgers Junction:

⇐ East - West ⇒

Track polarity for Stockton Passenger Station (please note that this diagram uses the reversed West-East notation specific to the Passenger Station schematics):

⇐ East - West ⇒

Track polarity at the Sonora-Branchline junction [*]:

⇐ East - West ⇒

[*] On the Sonora-Branchline schematic, it is important to note that the track polarity is fixed for the mainline, however that is not currently the case for the Branchline as its entire power district is connected via an LK100 auto-reverser. See 15.1- Reverse Loop for details. I will accept the above schematic as the desired polarity.

(See 4.3- Plans for links to higher quality PDF versions of these schematics).

5- Power Supplies

Under the layout are located many power supplies. Some have proven to be obsolete and not used anymore, and a few are critical. There is no obvious record of which so this section will try to explain what matters.

5.1- Older Power Supplies

In several parts of the layout are located large power supplies attached to the benchwork's support beams. These are totally unconnected. They are part of the original DC throttle equipment dating from the 60s. They are custom made and the schematics are available in the paper archives electrical cabinet. These are permanently mounted to the layout beams. At this point they are of purely historical interest as they show excellent craftsmanship. I left most of them in place, unconnected, and removed a few where space was needed for other equipment.

A typical “DC throttle” power supply. One per panel on the layout.

An example of these DC power supplies in situ, here the Stockton Yard panel.

Note the current-limiting light bulb at the top, as well as the DC-DCC relay on the left (with the purple/orange DCC power).

There were several modern MRC power supplies under the layout -- one under each tower and yard, which were connected to the remaining DC throttles. They have all been removed.

5.2- Building Illumination / Lights Power Supplies

Building Illumination

Many of the buildings on the layout have or used to have illumination.

All the building illumination is powered by a fairly old power supply located under the Valley Panel. It is actually used and delivers 9.30 V DC to the building lights.

That power supply is quite massive. It measures about 15 in x 25 in. Writings on it:

- Top right: “BLDG LTG POWER SUPPLY BLT 9/97”.

- Top left (by the terminals): “8 TO 14 VDC”

- Middle: “ADJUST”, with labels 1, 2, 3, 4.

- Bottom: “4 AMP SLOBLC”.

The fuse for the bulky 1997 power supply is a “5A 250V 313 Slo-Blow in a 31.75 mm (1 1/4") glass cartridge”. Here’s a mouser link for that kind of fuse. There are adequate fuses in a small box inside the Stockton Yard panel.

Right below the Valley Panel 1 are a row of unlabelled switches which controls the many building illumination circuits.

All the illumination power buses under the layout use white-with-blue wires pairs.

I had started an effort a few years ago to label a few of these circuits, or at least identify those which still work. Tracing the wires was hard, many went nowhere, and some went to buildings with either missing or burnt-out old-style bulbs (not LED). (update: cannot find these 2015 notes and started again from scratch in 2021).

In a typical fashion to this layout, there is no documentation that explains these circuits, and the panel itself has little writing on it. It’s a bit hard to read on the photo, so here are the labels:

- Panel on the left has a blue label “Scenic Lighting”.

- This panel has 9 toggles (picture is not complete above).

- It has two small labels “ON” at the top and “OFF” at the bottom (duh).

- White sticker on the 9th toggle from the left indicates “9”.

- Toggles 4, 5, and 9 are up.

- Panel of the right has 20 toggles.

- White sticker on the left indicates “10” and white sticker on the right most toggle indicates “29”.

- White sticker on the 7th toggle from the right indicates “RH” (I’d guess round house).

- Toggles 25, 28, 27, and 29 are up.

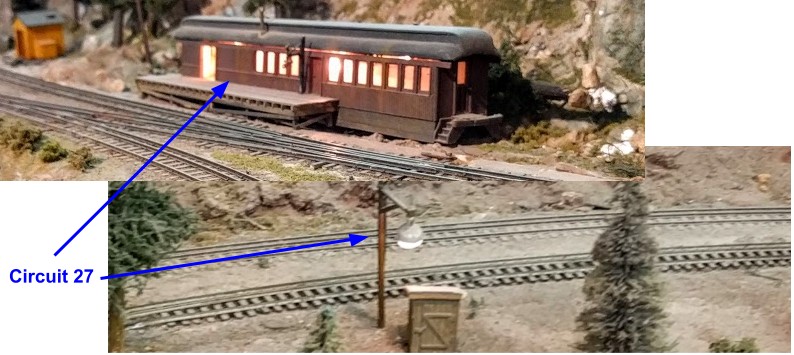

A nice effort would be to re-number these toggles and create a map of where they go on the layout and what works, what is missing. As far as I can remember, two of these toggles control the lamp post by Sonora and the illuminated car at Smith Flat on the Branchline. There’s also a working light in the McDonalds in Fairfield. A few other buildings in Fairfield and Stockton have wires which have been disconnected. Same for the roundhouse.

2021 Update

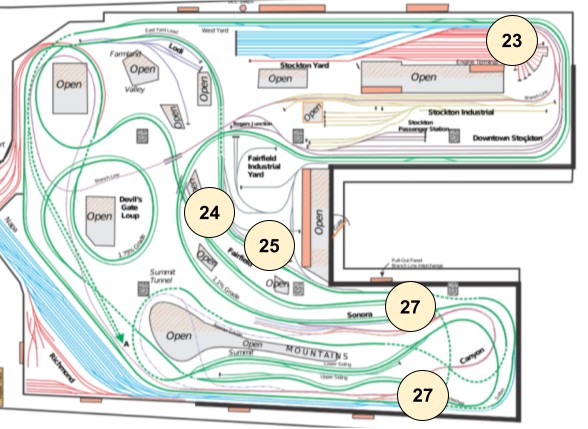

We spend some time understanding which toggles do produce any kind of lighting today. We could only find these below illuminating anything on the layout:

From left to right:

- 27 = Branchline, Sonora Street Light (by the branchline) and the illuminated car on the Branchline at Smith Flat.

- 25 = Mc Donald’s building.

- 24 = Fairfield street lighting (along the street with cars) + the Bekins yellow building.

- 23 = Labeled “R H”, powers a circuit in the Roundhouse (disconnected) + a shed nearby.

None of the other circuits seem to do anything. Either they are not used, or they go to places which are not connected, or dead lightbulbs. A bit more of this below; the bottom line a lot of crawling under the layout is involved to figure stuff out.

What we could see on the layout:

Circuit 23, “RH” (hard to see but there’s a wire with some blue tape in the roundhouse):

Circuit 24, Fairfield has many illuminated street lights, and Circuit 25 for Mc Donald’s interior:

Circuit 27, on the Branchline:

Representing these on a map of the layout:

As far as power level goes, the power supply:

- Delivers 15 V when all circuits are off.

- Delivers 10.3 V when the Branchline (27) is turned on.

- Delivers 9.3 V when the McDonalds (25) is turned on.

- Didn’t try with the Fairfield + RH on.

The branchline circuit seems to generate quite a significant power drop given the two paltry lights it powers.

It’s not a good sign to have such a voltage drop. The amps delivered were not measured. The guess is some of these use too much current and the power supply just can’t keep up. We may have to change it if we’re going to power more circuits with it.

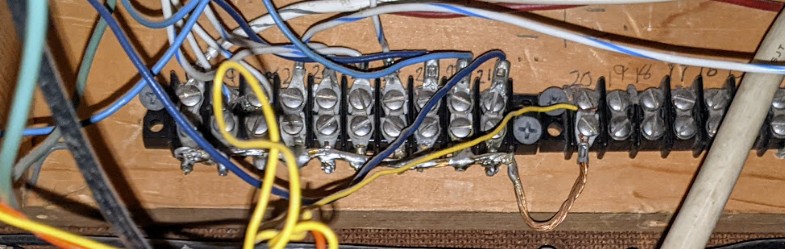

Now under the layout, we get to see an interesting story. First, on the other side of the row of toggles, we find this:

It’s a bit hard to see in that picture but there are a few interesting facts:

- Front toggles are numbered 1-to-29 from right-to-left (with only 3 number stickers visible, 9, 10, and 29).

- Terminal blocks on the back are fully numbered, yeah! Oh but wait, they are also numbered 1-to-29 also from right-to-left… See the problem here? Because they are on the other side of that panel, that means they are numbered in the wrong direction. Essentially front panel toggle #29 connect to terminal block #1, and front panel toggle #1 connects to terminal block #29. This will make any engineering discussion quite interesting.

- Even without zooming on that picture above, it’s clear a lot of these circuits are not used.

- Out of the 29 circuits, there are 10 wires leaving the panel towards Fairfield, and 3 wires leaving the panel towards the Roundhouse.

- All the wires have the same color… including the ground ones. Mostly. Yes, lovely.

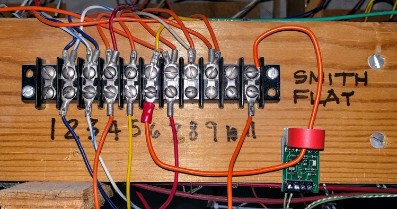

Next to that terminal block, the perpendicular support has this labeled terminal block:

The white-with-blue wires are the building light circuits. They just pass through. The green wires are the ones going to the terminal with some labels about blocks. Not quite sure which bus that is, as green wires like this are typically used for turnouts in pairs with white wires, and red wires to block power; yet the labels are more indicative of block power. Another mystery for another time. In any case, this labelled terminal block is not relevant to the building lighting.

Anyhow, looking at the details of the terminal blocks, there’s a large 20-position on the right that is unused. Then it’s followed by a 10-position block that seems to be mostly all for common wires judging by how the bottom terminals are all bridged together:

The only circuits that are wired are on the terminal blocks on the left side:

We need to keep in mind that the numbers are inverted with regards to the toggle panel. On the very right side, the big white-with-black wire is likely a ground. Then the one next to it goes to panel toggle #29. From this, it looks like we only have 12 outgoing circuits. That more or less matches the bundles of wires we see going out towards Fairfield (about 10) and towards the Roundhouse (about 3, including ground).

One of these wires from the 10-ish bundle going towards Fairfield seems to loop back under the Stockton Station. However it’s not clear where and if it is used. The Stockton Station has its own lighting circuit which is done using a completely redundant and independent old Bachman DC power pack, with nothing happening when we tried to power it on.

One realization is that these were powering incandescent bulbs, likely the 12 V kind. As long as the original installer could identify two wires per circuit, they did not really need to know which was ground as the polarity does not matter. It’s going to matter when we power lights via a DC step-down converter or a LED circuit though.

Neon Signs

Under the Mountain panel, there are two small power packs. One powers the motel neon sign in the Fairfield town and appears dead. Another one used to power the grade crossing signal at block 120 before the signal and its electronics were removed by a former member with little consideration.

Under the roundhouse, there are 3 small power packs. They power the hotel sign in the town, the theater sign, and the building on fire next to it.

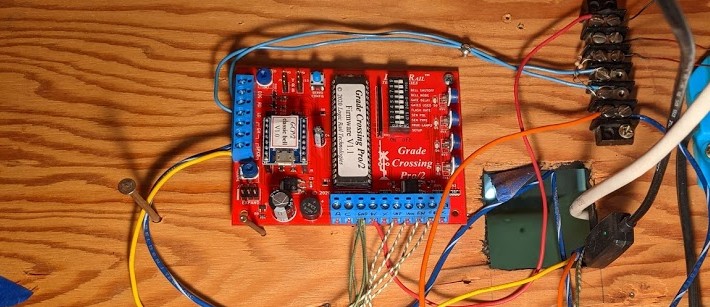

Grade Crossing

2021 Update: The grade crossing has been reinstalled from scratch in 2020-12. It uses a 9 V AC power supply located next to the control module, under the Mountain Panel. See details in section 10.4- Fairfield Grade Crossing.

5.3- Critical Power Supplies

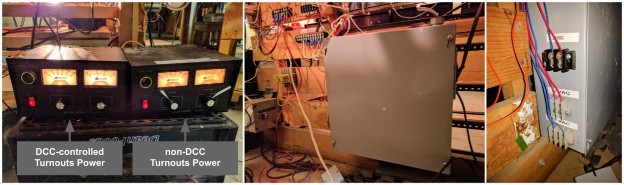

Right behind the DCC Command Station are located 3 critical power supplies:

- A small regulated variable voltage power supply (with 2 knobs and 2 analog meters) is dedicated to the slow-motion turnouts. It's labeled with a "11 V MAX" label.

- Next to it, a similar looking regulated variable voltage power supply was added for the new DCC-controlled turnouts.

- On the other side of the DCC Power Pro is a large gray power supply which is now called the “Auxiliary Power Supply”. It has 3 outputs which provide:

- 24 V DC for the DC / DCC relays.

- 12 V AC for an accessory bus going under the layout, powering various little things (example: tortoise from the branchline, ac-dc converter for the Sonora signal bridge, etc.)

- 6 V AC for … definitely some lights but what else?

Update: the Auxiliary Power Supply has been moved to the fascia, next to the automation computer, to make it more accessible when it trips:

5.4- DCC Power

The layout uses an NCE Power Pro and three NCE 5-amps boosters which are then split in 10 power districts.

The NCE Power Pro (left) and 3 boosters

Each power district has its own NCE EB1 electronic circuit-breaker for protection against shorts.

The circuit-breakers for the 10 DCC power districts

Map of DCC boosters to power districts to blocks (see warning below about voltages indicated):

Booster |

Usage (number of engines [1]) |

Level / noise [2] |

Booster 1 (NCE Command Station) |

P1 V1 (Valley1) … 1 P1 STKYD … 2-4 |

|

Booster 2 |

P2 V2 (Valley2) … 1 P2 NAPA … 0 P2 TOWN LODI … 0 P2 FAIRFIELD … 1 |

|

Booster 3 |

P3 MTN-1 … 1 P3 BRN RCH-2 … 1 |

|

Booster 4 |

P4 MTN-2 … 1 P4 BRPORT … 0 P4 SIA RND … 0 P4 STK STN … 1 |

Note 1:

- The middle column indicates the name of the power district supported by each booster. Each power district has its own circuit breaker. The “number of engine” is a crude estimation of the load of that district in number of trains typically using that district either during a Saturday ops or a weekday automation. Saturday trains typically have more than one engine.

- Projected extra power districts: Fairfield Industrial on Booster 2, and Stockton Passenger Station on Booster 4.

Note 2:

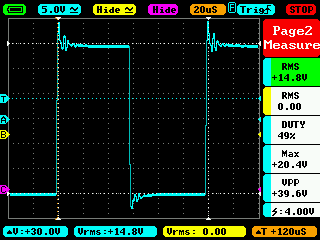

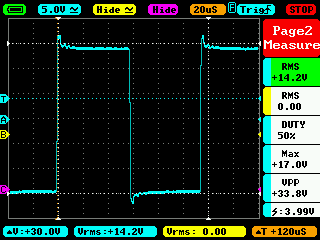

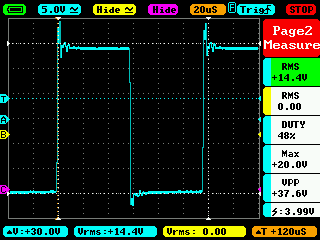

- The waveform measurements were done without any load (a.k.a. engines) running on the track.

- Warning: the RMS indicated on these voltage measurements is not accurate. You can find an explanation of why the RMS is wrong on this DCC Wiki page. However the RMS values give a good relative indication and most importantly displays the ripples in the waveform.

Note 3:

- Mountain Panel 2 (left side) is P4; Mountain Panel 1 (right side) is P3.

- Valley Panel 1 (left side) is P1; Valley Panel 2 (right side) is P2.

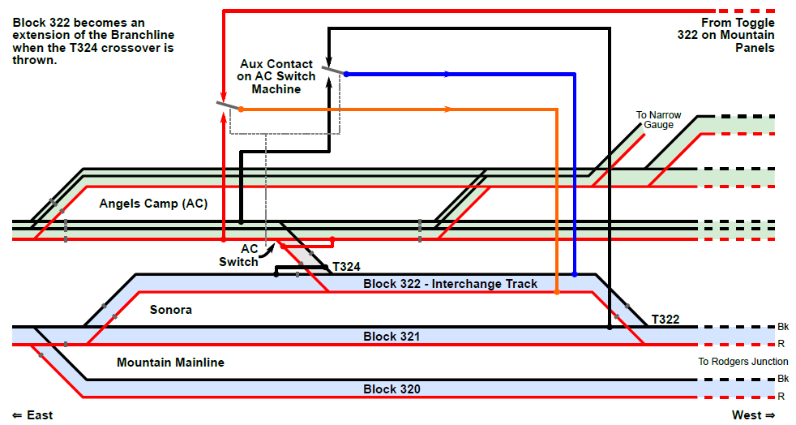

Both control towers (Mountain and Valley) are powered by two boosters each. The block toggles are used to select one booster on one panel for a set of blocks and the other booster on for the rest of the panel. Here’s the split for the Mountain panel, followed by a detailed explanation below:

The DCC conversion made use of the block system and kept it intact. Since each block has two possible power sources, the DCC actually acts as one of the power sources. For example on the Mountain tower, there are Panel 1 and Panel 2 for block control, half of the block toggles on one panel toggle it to DCC whereas the other half is located on the other panel.

These DCC toggles are denoted by a yellow handle. The example above is the Mountain Panel #2. There are two such panels, identical, except:

- On Mountain Panel #2:

- Toggles for blocks 310 through 371 are up (on). That panel is connected to booster 3. The toggles have been painted yellow.

- Toggles for blocks 400 through 462 are down (off). This means these blocks are not powered by booster 3.

- On Mountain Panel #1, the situation is reversed:

- Toggles for blocks 310 through 371 are down (off). This means these blocks are not powered by booster 4.

- Toggles for blocks 400 through 462 are up (on). That panel is connected to booster 4. The toggles have been painted yellow.

- The end result is that:

- All blocks 310-371 are powered by booster 3 via Panel #2.

- All blocks 400-462 are powered by booster 4 via Panel #1.

Technically each panel is powered by a “power district” (e.g. one of the EB1 circuit breakers). These are in turn powered by boosters 3 and 4. The whole point of this scheme is obviously to power the long mainline using multiple boosters.

Since each block has two power supplies in parallel (booster 3 & 4 via panel 1 & 2), when operating it is important that one block toggle be up whilst the corresponding block toggle on the other panel be down, otherwise it does short two power districts / boosters together, which is not good. I’ll detail below how this is wired behind the panel.

The rule when operating in DCC, as is the case here, is that all "yellow" DCC block toggles must be up and all the silver DC ones must be down. There is no written indication on the panels that they work that way. It’s fairly error prone.

To finish here’s a quick survey of the DCC signal measured at different points on the track:

5.5- Room Outlets / AC Power

The room breaker panel is located behind the Pullman exhibit, on the right side when entering the room. At this location we also have the main “North & South” power toggles to turn on power to the layout.

The circuit breaker has an inscription on the cover as having been updated in 1995. Although there are labels for each circuit, they have been further annotated, and their veracity has not been verified. There is also a very prominent “240 V” warning label on it. This breaker is actually a sub-breaker, which power comes from a larger breaker in the heater room. The train room breaker labels read as such (caveat emperor):

- 1 = North & South Flourescents (sic). Back room Lights.

- 2 = North Layout Outlets.

- 3 = Center Fluorescents (crossed). Dryer Animal Room.

- 4 = South Layout Outlets.

Back Room Unswitched Outlets.

Show Lights 1 & 2. - 5 = Center Flourescents (sic) / Animal Room Emergency.

- 6 = Show Lights 3 & 4.

- 7 = Animal Room.

- 8 = North & South fluorescents. Back Room LIC (sic).

The only circuit that has been verified is that #4 does toggle the one backroom unswitched outlet that we need for the computer equipment. The label indicates “Outlets” plural, when only a single outlet was found on this circuit. There might be others located behind cabinets that we cannot easily move.

What are the North & South Circuits?

The room has two rows of concrete pillars: the ones on the left side of the room (by the kids train exhibit, mountain side of the layout) are on the “South” circuit, and the ones on the right side of the room (by the Valley panel) are on the “North” circuit.

One of the outlets of the back room is on a different circuit that is not toggled with the rest of the layout power.

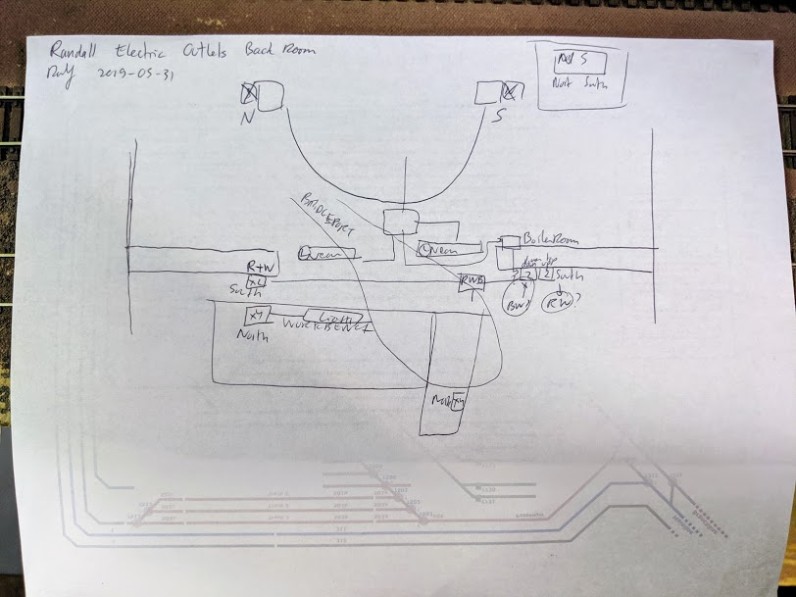

Crude schema of power in the back room (to be cleaned up later):

Details:

- The workbench is on the North circuit.

- The two outlets at waist level on the concrete walls of the backroom are on the South circuit.

- Only the low-to-the-ground outlet on the mountain side of the back room is on the “back room permanent” circuit.

6- DCC Bus Wiring

Pairs with one orange cable, one purple cable, and one dual white cable: the orange/purple are fairly large AWG, maybe 12 or 14, stranded. The white one is regular power cord cable.

The orange/purple cables are the output of the DCC circuit breakers and they bring power to each DCC power district. The white cables are connected to the 24 V DC panel and trigger the DC / DCC relays once the DCC main switch is turned on.

6.1- DCC / DC Power Relays

This can be seen next to the DCC Command Station where the circuit-breakers are located:

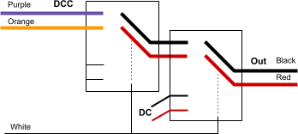

Under each tower panel (one per block panel), there's a relay with the other side of the orange/purple cable. The relay acts as a dual 1PDT that toggles between the DCC or the DC input: This double-relay scheme means that some DCC-only equipment can be powered only when the DCC is up (see 11- Branchline below for an example). The output are the two large black and red wires. |

How this is used depends on the control panels. There are different cases for yard panels vs the mainline control towers.

6.2- Block Power for Yard Panels

The yard districts are each powered via their respective yard panels, which typically feature both block power toggles and turnout toggles.

For most yards, there is first one 3-position selector to select the power feeding the whole yard, and then each block has a simple on/off power toggle. Typically the 3 power selections depend on where the yard interconnects with the mainline. We need to remember this was designed for DC usage, which track voltage dictates train speed. In this mode of usage, it is typical to power either the full yard or at least an interconnection track with the mainline, bring the train in or out from the mainline, and then switch the yard to its own independent yard power pack.

I’ll give two examples as these are the cases I had to look into to solve issues.

Richmond Yard has the choices of Throttle 1, Throttle 2, or Yard. The “throttle 1” and “throttle 2” cases are connected to the mainline’s DC throttles. Once a train is in or out of the yard, it can be changed to its own yard DC power pack.

DCC conversion of Richmond Yard: Throttle 1 is connected to the DCC bus, on its own booster / circuit breaker. Throttle 2 is not connected to anything. The DC yard power pack is still present but not powered and not used.

Down the line, it would be useful to clean that up by replacing this 3-position toggle with a simple on/off toggle, only connected to the DCC bus. This would prevent operator errors not understanding why the whole yard loses power.

Stockton Yard also has two unrelated power selectors.

- The two interconnection tracks (in yellow) going to/from the yard to the mainline have a selector with three choices: M, Y, V. “M” is the power from the one of the Mountain Panels (as selected by the Front Yard toggle there which selects Panel 1 or 2), “Y” is the yard’s dedicated DC power pack, and “V” is the power from the Valley Panel (as selected by the Front Yard toggle there which selects Panel 1 or 2),. This dictates what the Stockton Yard panel receives when set on the V selector.

- The interconnection track (in red) going to/from the Roundhouse Yard has a selector with three choices; Rh, Off, Yd. This allows the track to be powered from the Roundhouse panel, be off, or be powered from the yard throttle.

For the DCC conversion:

- The “Y” side is connected to the yard’s DCC input which comes from Booster P1 with its own circuit breaker. This is the only recommended position in DCC.

- The “M” side is connected to the output of the “Front Yard” toggle on the Mountain Tower. This is not recommended in DCC.

- The “V” side is connected to the output of the “Front Yard” toggle on the Valley Tower. This in turn connects to the Valley Panel 1 (Booster 1) or Valley Panel 2 (Booster 2), which each have their own circuit breakers. This is not recommended in DCC.

In DCC, it’s important for the “M,Y,V” selector to be set to Y. It means the interconnection track is protected by the same circuit breaker as the rest of the yard. For a while it was incorrectly set to “V”, and although everything seemed to be working fine, it meant that any short in the yard would also short the mainline, thus producing hard to understand issues.

Down the line, it would be useful to clean that up by replacing these 3-position toggles with simple on/off toggles, only connected to the yard’s DCC bus. This would prevent operator errors toggling these by mistake and not understanding their consequences.

6.3- Front Yard toggles on Mountain and Valley Panel

The interchange tracks in the Stockton Yard panel are powered via a 3-position toggle:

When the Stockton Yard power selector is on “V”, power is selected from either Valley 1 or Valley 2 using the “Front Yard” toggle on the Valley panel. It’s a 3-position toggle, and the middle one is unused, leaving the wire unconnected.

When the Stockton Yard power selector is on “M”, power is selected from either Mountain 1 or Mountain 2 using the “Front Yard” toggle on the Mountain panel. It’s a 3-position toggle, and the middle one is unused, leaving the wire unconnected.

A label was added to make it easier to remember which sides selects power from which panel:

When the Stockton Yard power selector is on “Y”, power used to come from the local DC throttle, which is now connected to the yard’s DCC power district.

6.4- Block Power Selection for Mainline Control Towers

As a recap, each panel receives DCC power directly from a circuit breaker. Under the panel, a relay is used to select DCC vs DC power source.

The relay acts as a dual 1PDT that toggles between the DCC or the DC input:

In the Mountain Panels and the Valley Panels, the DC side was further connected to two additional relays to select between DC and DCM inputs. The DC part could further come from MRC power supplies using radio throttles, or from local wired “knob” DC throttles.

Let me rephrase that to let it sink. That means the power source for each of these panels can come from:

- A local “knob” physical power pack.

- A local DCM power pack.

- A local MRC Radio Control power pack (with its associated walkaround analog radio throttle).

- A DCC booster (via a dedicated DCC circuit breaker).

Furthermore, each individual block can be powered from either the panel 1 or panel 2 of its corresponding tower.

As part of the DCC simplification, we removed the dual relays and the DC/DCM power sources to simplify the panels, and the DC part of the relay is not connected to anything anymore. The main relays were left in place as they can be very handy (I typically simply remove the relay from its socket base to disconnect an entire panel and work on it).

On the output side:

- The black wire goes (indirectly!) to the DCC power bus.

- The red wire is split and then fed to the smaller red wires for each block toggle.

Black Wire Side

For a while I naively assumed the black wire out of the DC / DCC relay was connected directly to the DCC bus going to the track. It turns out that’s not the case. Both the Mountain division (Mountain 1 & 2) as well as the Valley division (Valley 1 & 2) are each wired with all the “common grounds” wired together. These are located under the Valley Tower panels.

Under the Mountain panel, this terminal bridges both Mountain 1 and Mountain 2:

Every single block in the Mountain division has its black rail wire connect to this bus bar, located under Stockton Yard:

Each black wire connects to a specific block in the mountain (which is on the very opposite side of the room), they are all interconnected together with the bus bars, and from there two black wires go back to the Mountain Panels in the middle of the room. As can be seen in the middle, both bus bars are bridged together.

A side effect of this is that it absolutely merges the “common” from boosters P3 and P4.

For the Valley division:

(TBD… get a better picture and add it here).

And finally this merges all the commons together for all the “isolated” yards:

This is also located under Stockton Yard.

An important note: it should thus be assumed that none of the four DCC boosters are actually isolated from each other. A safe assumption is that all their common/black/negative outputs are eventually cross-linked somewhere under the layout.

Red Wire Side

The output of each block toggle connects to an interconnection board under the layout using red wires (see picture above in 4.1- Wiring). For each block, the interconnection board takes two red wires from Panel 1 or Panel 2 of the mountain or valley panel, and outputs one red wire towards the track block. The red wire then joins the black wire and forms the DCC power bus for that block, on which feeders are connected to the track.

To understand how power selection, let’s look at the control panel of the Mountain tower, for example:

There are two panels, “Panel 1” and “Panel 2” which are replicas and have the same track layout with the same block toggles. Earlier I explained how this is used to power half the blocks from one power district and the other half of the blocks from another power district and thus different boosters.

Each block has a number and they are equally present on each panel. However on Panel 1 only half the toggles from the top are connected to DCC whereas on the Panel 2 only the ones from the bottom are connected to the DCC. The output of each block of the same number is connected together via the interconnection board indicated earlier under the layout, thus merging both sides.

This is the wiring behind the scene:

Since there are about two dozen blocks on each panel, each panel powers about a dozen DCC blocks. There is a similar setup for the Valley panels.

Now this requires a little bit of a discussion. The schema above is definitely complex and may seem odd to someone used to modern DCC bus wiring. It does make more sense when one considers this was a pure-DC layout: two independent DC throttles would power Panel 1 vs Panel 2 (thus different voltage for different speeds) and block toggles on the panels would allow a given block to be powered by power supply 1 or 2. The DCC conversion reuses that and instead powers the panels from booster 3 or 4.

Consequently it is crucial that a given block be OFF on one panel and ON on the other one, but not turned ON on both at the same time -- otherwise it literally shorts two boosters together.

I expand more on the issues for DCC wiring in section 6.8- How Not to Wire a DCC Layout below.

6.5- Valley DC Power Selection

The Valley Tower with its power panels 1 & 2 follows a fairly similar scheme to the one described just above for the Mountain Panels.

It does have one extra little twist which is worth noting, with this selector located under the panel to choose between “Knob” and “Radio” for the Valley 1 panel…. (there’s a similar setup on Valley Panel 2).

This deserves some scrutiny and understanding.

To start, on the second image above on the right side we can see the DC / DCC relay (only the base socket, I typically remove the relay itself when I work on the wiring, to ensure electrical isolation). The DC input used to be from the top of the relay socket and has already been removed.

The two large black and red wires at the bottom of the relay socket are the output for the panel. However they do not connect directly to the panel.

Instead the output of the relay is connected to the “Knob / Radio” selector on the Radio side. This in turn is connected to that terminal block seen in the second picture on the left side.

Finally the red and block wires seen on the terminal block are connected to the block panel 1.

The schematic of the power routing can be explained as such:

This explains where the “Throttle 1” can be powered from for the Valley Panel 1:

- From the DCC -- in this case the output of the DCC Command Station via an EB1 Circuit Breaker.

- From the MRC Radio Control (analog DC supply).

- From the DCM (analog DC supply).

- The output of this goes to the “Radio” side of the selector knob under the panel.

- The “Knob” side was connected to a custom-made “power pack” (DC supply) with a large knob and two vu-meters.

- The output of this selector goes to the panel -- at least the red wire goes there directly, whereas the black wire goes to the common bus bar that collects all the black wires from each block.

As part of the DCC conversion:

- The MRC analog radio, the DCM analog DC, as well as the “Knob” power pack all have been removed.

- The panel has been connected directly to the DC / DCC relay.

The Valley Panel 2 has exactly the same setup.

6.6- Common Rail

As far as my limited understanding of such things goes (a.k.a. “please correct me if I’m wrong”), then I’d tend to say the layout uses Common Rail wiring and what exactly happens between power districts is mostly clear to me.

As an example, let’s take the Mountain division; please refer to the overview simplified schematic provided in the previous section. The division is covered by 20-30 blocks and two panels (Mountain 1, Mountain 2). Each panel is powered by its own booster via an EB1 circuit breaker. Black and red power busses deliver power to the track. The black wires run (indirectly) from the panel’s DCC black to the DCC bus and the track feeder’s black wires. The red wires are first routed via the panel for the various block toggles -- and for each block, power for the “red” feeder wire can thus come from the panel 1 (booster 3) or panel 2 (booster 4). However the return black wires are all connected together via an interconnection bus (see picture below).

Question is what happens between panels, for example are all the black return wires from Mountain Panel 1 eventually also connected to the ones from Panel 2, even though power originates from different boosters? The answer to that is definitely yes as shown in 6.2- Block Power for Yard Panels.

But what about between panels from Mountain Tower and Valley Tower, are their commons also connected together? Anecdotal testing indicates that they are indeed connected, although it’s not clear how and where.

Similarly, although each yard can have its independant DC power supply, their common grounds are all interconnected.

Follow up question: since the layout uses common rail, have the boosters been modified to follow the NCE procedure to use them with common rail wiring (link here)? In this case, yes they have -- each booster was opened to double check, and the screw YY to isolate the booster from the ground had been removed. And in this case, should the NCE procedure to ground the case of all the boosters be followed? Yes and no. It’s mostly useless -- the point of that NCE procedure is to isolate the boosters since removing the screw YY isolates the booster’s metal enclosure from the circuit board and to prevent the outputs from being grounded together via the boosters’ metal enclosures -- however that point is rendered moot since the layout effectively grounds all boosters commons together anyway. Still I think it’s good to have the metal enclosures grounded so I added that.

One must realize that the NCE procedure’s goal is to isolate each booster's common wiring. That’s why the screw YY is to be removed. Which conflicts with the design of this layout where all the commons are voluntarily reconnected together after yards and yards of extra useless wiring. We cannot achieve proper booster/district isolation without a very involved rewiring of the entire layout.

Some (all?) district common grounds are interconnected. This is located under Stockton Yard.

All common wires for Mountain 1 and 2. This is located under Stockton Yard.

6.7- Electrical Standards

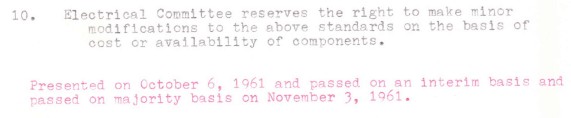

From the 1961 paper archives of the layout:

The following table is based on visual observation of “key” wiring under the layout. The list is not exhaustive.

Gauge |

Color |

Era |

Usage |

12 AWG Stranded |

Black + Red |

DCC |

Boosters to EB1 circuit breakers. |

10 AWG Stranded |

Orange + Purple |

DCC |

DCC EB1 circuit breakers to DC/DCC relays on panels. |

16 AWG Stranded |

White extension-cord pair |

DCC |

Trigger for DC/DCC relays. 24V AC. |

16 AWG Solid |

Red + Yellow |

DCC |

Used in “new” DC power buses. |

16 AWG Stranded |

Speaker Wire |

DCC |

Used on “newly” installed turnout rotary toggles typically to newer Tortoise switch machines. 12V DC. |

16 AWG Stranded |

Green + White |

DC |

Used in old turnout rotary toggles from Mountain/Valley panels. 12V DC. |

~22 AWG |

Communication Wire (Black, Red, Green) |

Automation |

Used for short-distance sensors to NCE AIU01 on Passenger Panel. |

24 AWG Solid |

Green + Green/White twisted |

Automation |

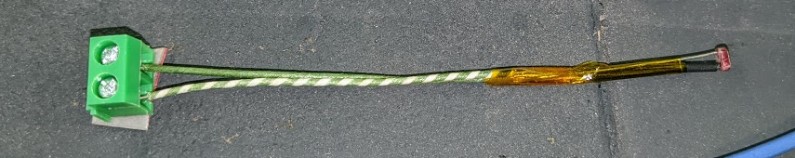

Already twisted. Used for BD20 sensors & connections to NCE AIU01. |

Notes:

- Solid = Not stranded.

- 16 AWG stranded wire is not marked so that’s just a visual estimation; it could be 18 AWG.

- The 10 AWG wire that brings DCC to the Mountain and Valley panels first connects to some terminal under the layout, and from there goes to the panel using unmarked 16 AWG stranded wire.

- “New” means stuff likely dating from the DC/DCC conversion, so after 2010-ish.

- Era: DC < 2010. DCC >= 2010. Automation >= 2016.

My own electrical standards are as follows:

Gauge |

Color |

Usage |

10-12 AWG Stranded |

Black + Red |

DCC Power Bus. |

16-18 AWG Solid or Stranded |

Black + Red (ideal) (as available) |

Low power DC Power Bus. 12V DC or AC. |

16-18 AWG Stranded |

Green + White |

Turnouts Power. 12V DC or AC. |

22-24 AWG Solid, twisted |

Green + Gr/White |

Block detectors, sensors, low power short distance 5V wiring. |

RJ12 6P6C Straight |

Gray |

NCE Cab Bus. |

Note: Polarity is extremely important for all DCC buses on this layout due to the heavy common ground influence. Always assume all blacks are connected together. When there are power block toggles, only the red side is interrupted.

6.8- How Not to Wire a DCC Layout

The current wiring on this layout does not follow modern DCC practice.

As noted above, the current situation is the result of adapting a former DC layout to also support DCC. I think the transformation was cleverly done given the initial medium; however it results in a DCC layout with poor electrical performance.

Let’s look at what one should do to properly wire a club-sized layout in DCC:

- Have a strong & consistent convention defining wiring gauge sizes and connections.

- From its original construction as a DC layout, it’s clear the layout had clear 6.7- Electrical Standards, and these are fairly well followed on the majority of the mainline. The original yards (Stockton and Bridgeport) are also very consistent.

- However that’s not the case with later additions. The Branchline follows different electrical standards for wiring (but it’s fairly consistent); and Lodi itself is extremely inconsistent.

- The wiring between DCC boosters and then panels is consistent, and matches reasonable electrical standards.

- The current DCC practice advocates using twisted pairs for DCC buses over 30 feet (and even below if possible). This avoids crosstalk and reduces unbalanced noise issues in the digital signal. We totally lack this here, and it shows several issues with some specific brands of decoders (e.g. the BLI ones, which are finicky at best).

- That was not a practice needed in DC, and as such is not followed here.

- On the contrary, we have unbalanced black vs red wiring following dramatically different paths, with all wires mixed together with other wiring from the layout such as turnout control or accessories power buses.

- The path taken by the DCC power bus from the DCC boosters to the track can be well over 30 feet. The biggest culprit is probably the Mountain Districts wiring: A random back-of-the-envelope estimation is that going from the DCC boosters / circuit breakers to the Mountain Panel is probably 30 feet of wiring all by itself and is using non-twisted wire. Then the DCC wiring goes through the panel itself (2 relays + 1 block toggle + 1 terminal + 1 interconnect bar) before leaving for another 10-30 feet before reaching the blocks’ feed wires. On top of that, the return path (the “black wire” of the DCC bus) on the Mountain division follows some kind of complicated and unusual path adding about 50-60 feet of wiring (see 4.1- Wiring).

- Power districts and booster isolation.

- This is achieved on a DCC layout by having gaps on both rails between power districts. Only gaps for block detection can be made on a single rail.

- This layout uses the DC “common rail” design (see 6.6- Common Rail). Even when the track has gaps on both sides, the common rails are bridged together at the main panels, and in turns all the common grounds for all panels and power districts are bridged together at a central location under the layout.

- To make matters worse, there are various interconnects between the panels to cross-feed a control panel using the power from another power panel. This can potentially bridge different boosters together.

- We still have some “phantom power” on some blocks. In specific places, even if I turn the block off using the panel toggles, the track is still powered with some kind of DC-offset signal from some other place which I do not manage to trace. That means there are some cross-feed power connections I still do not understand nor control.

7- Mainline Turnouts

Turnouts control represents another interesting topic.

The layout uses 3 kinds of turnouts: twin-coils, Fulgurex and Tortoise. It seems that twin-coils are used in the yards and the original mainline was apparently using Fulgurex turnouts. Later, some of the mainline and yard were changed to more modern Tortoises.

Turnout panels use rotary switches for Tortoise and Fulgurex turnouts (mainline) and push-buttons for the twin-coils (all yards).

The existing turnout panels all use non-momentary rotary toggle switches.

Power is provided by a regulated variable DC power supply located next to the DCC Command Station as indicated above.

Each rotary toggle switch is a 6PDT with only 2 poles used, so it ends up being the typical DPDT wired in a cross-over configuration. Turning the toggle effectively inverts the input polarity.

Input is the DC turnout power (red wire is negative, white wire is positive). Inside the panel, all red wires are connected together using a terminal block where all terminals are connected together with a bare wire.

Output of each DPDT is 2 wires, white and green. The whites ones travel directly to the corresponding turnout. The green ones are connected to another 1-to-1 terminal block inside the panel.

Schematics of the original wiring:

Each panel has about 20 turnouts toggles. In that case, the white input wire is a common wire. The red terminal blocks splits in the single red input for all the turnouts. On the output side there are as many white/green pairs as there are rotary toggles.

It’s important to note that these rotary toggles are permanent contacts. This works well with Tortoise or Fulgurex.

The yards use momentary contact push-buttons connected to yard ladder matrices and twin-coil turnouts.

A few miscellaneous notes:

- “Old” twin-coils (as still found under Fairfield or in the yards) are powered by a 12 V AC bus. They are not DC-compatible. Regarding those from Fairfield, only half are working properly; the other half either have one coil not working or mechanical issues or both. Yard ladders for Stockton and Napa use twin-coils and are working properly.

- There’s a box of 10-20 of these in the electrical cabinet which have been removed from the layout. I was told the reason is they were partially dead and replaced by Tortoises.

- The Branchline has Tortoises setup in places such as the interchange tracks. These are powered via the 12 V AC bus using 2 diodes (see below for details).

- A handful of turnouts on the mainline are not operative. They are either old twin-coils disconnected, or Fulgurex that don’t work. Some are not connected or lack a rod/wire. Examples are Walong (block 400) and the mainline in/out of Fairfield.

Failure modes / known issues:

- Twin-coils:

- Symptom: A turnout that easily throws in one direction yet fails to throw in the other direction.

- Reason: Often one of the two coils seems to have failed.

- Solution: Replace whole assembly or do not use.

- Twin-coils:

- All the layout twin-coils are of the 12 V AC type.

- Coils can be either DC or AC. The ones used require an AC voltage.

- They will not work if powered by the Turnout Power Supply used for Tortoise / Fulgurex.

- Fulgurex:

- Symptom: A Fulgurex that seems to slow throw in one direction yet too weak/slow to throw at all in the other direction. Measuring the voltage will show they receive less than their required 10 V.

- They require a fairly strong current, nominally 200 mA at 10-12 V.

- They cannot be powered directly either by a Digitrax DS64 or an NCE Switch-8 -- Note: I did have some success with the DS64 but it’s really hit-and-miss and as such is not recommended as it exceeds the amps output of the DS64. In this case, the 12 V output from the DS64 collapses to 3~5 V, which is not enough.

- Fulgurex / Twin-coil:

- Symptom: Trains stutter when crossing the frog.

- Reason: The frog is powered via contacts on the point motor. Oxidation of the exposed contacts creates some resistance which reduces power delivered to the engines. Measuring with an ohmmeter will typically show a non-negligible resistance (e.g. 100 Ω).

- Solution: Either swap the point motor, or at least try to clean the exposed contacts using some CRC 2-26.

- Twin-coil:

- On some of the twin-coils, the contacts have obviously lost their springiness and no longer make a good contact.

- Solution: Swap the whole unit. Trying to bend the contacts has never proved successful.

- Fulgurex:

- In one instance, the DPDT contact spring had gone AWOL.

- Solution: Replace the spring in place from another Fulgurex. It is possible, albeit tedious. Or swap the whole unit.

8- Stockton Station & Stockton Yard

8.1- Stockton Station

The Stockton Station is certainly the most visible feature of the layout when visitors walk in the room and approach the middle of the room.

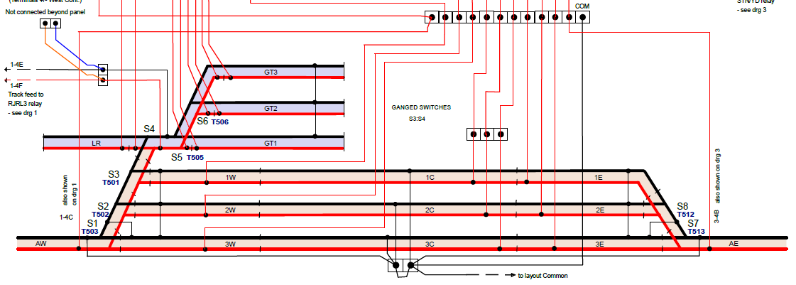

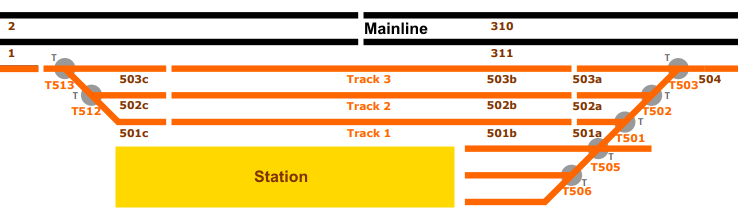

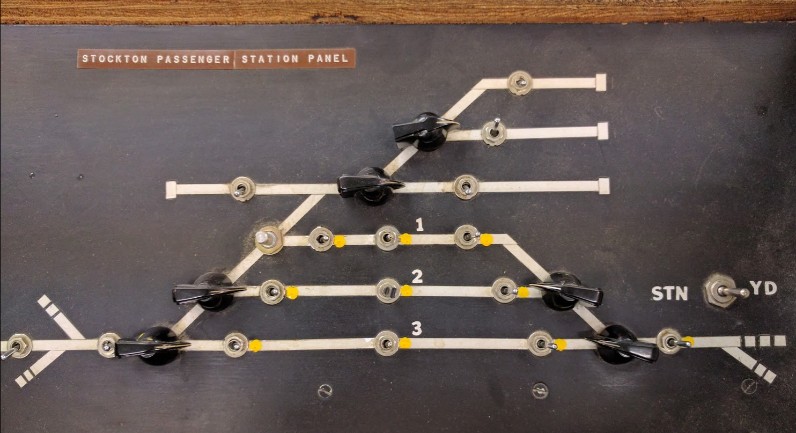

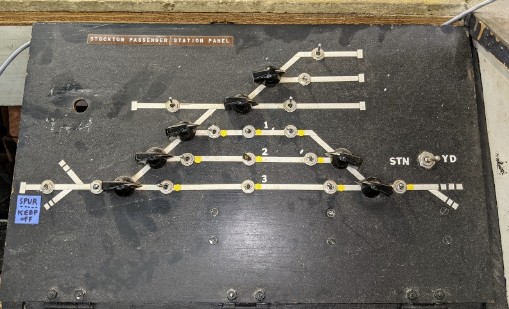

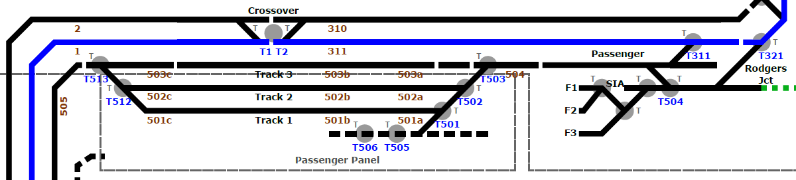

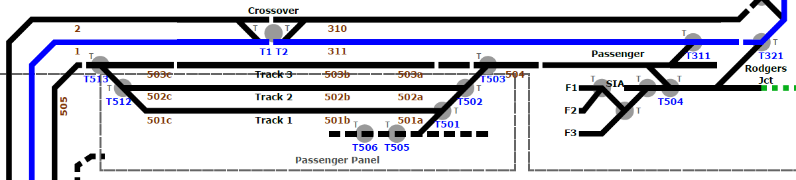

Track plan:

Control panel:

DC operation, as explained by Mr. Perry:

- The station is connected to the East (right side) to the mainline, or the Stockton yard, or the roundhouse lead. This is the Approach East block.

- The station is connected to the West (left side) to the mainline at block B311 or the branchline via T504. This is the Approach West block.

- Tracks 1, 2, and 3 for the station are composed of 3 segments (West, Central, and East), each with a power selector: left for West approach, middle for off, and right for East approach.

- Power for West comes from:

- Block B321 if T311 is thrown to connect the station to the mainline track #2.

- Block B320 if T311 and B320 are thrown to connect the station to the mainline track #1.

- Branchline if T504 is thrown to connect the station to the branchline.

- Otherwise from a local West Power Controller (no such power supply was installed though).

- Power for East comes from:

- Block B10 when T04 is thrown, connecting the station to mainline track #1 in front of the yard.

- Block B21 when T04 and T05 are thrown, connecting the station to mainline track #2 in front of the yard.

- The Roundhouse Cab power when T604 is thrown, connecting the station to the Roundhouse Lead.

- Or the Stockton Yard power when neither of these turnouts are thrown and the STN/YD switch is set to YD.

- Or to a local East Power Controller when the STN/YD switch is set to STN, or T03 was thrown. No such power supply was installed on the layout, though, so in this case the station would have no power.

- The 3 spurs at the top have their own power through the West Power Controller.

(Important Warning: all the Passenger Station schematics by Mr. Perry uses a reversed West-East notation, which contradicts the one used by the rest of the layout; I kept the description above intact because the names are on the layout wiring, but I want to make it clear that they are the reverse of my convention of East-West meaning Left-Right meaning a clockwise run; on my schematics I use block numbers instead of names to avoid this kind of confusion).

When the layout was powered in DCC, DCC was injected on the “right” side (East approach) and would indirectly come from either the mainline, the roundhouse or the stockton yard (by default). That’s the reason why each block power selector has a “yellow dot” on the right, to indicate this was the default setup. The inconvenience of this scheme is that the station would lose power when T03 was thrown, or the STN/YD switch was thrown to STN side.

TBD 2020: Document changes done to power relay on T03.

8.2- Stockton Yard

The Stockton Yard is actually composed of two different yards: a freight yard and a passenger yard. There’s an engine facility as well as a roundhouse. Note: An overview of both yards as well as a track plan were provided in section 1- Layout Design and won’t be repeated here; instead we’ll focus on some details.

One particularity of the yard is that it connects with the mainline via a double slip switch and a crossover which are controlled from the two different panels: