The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

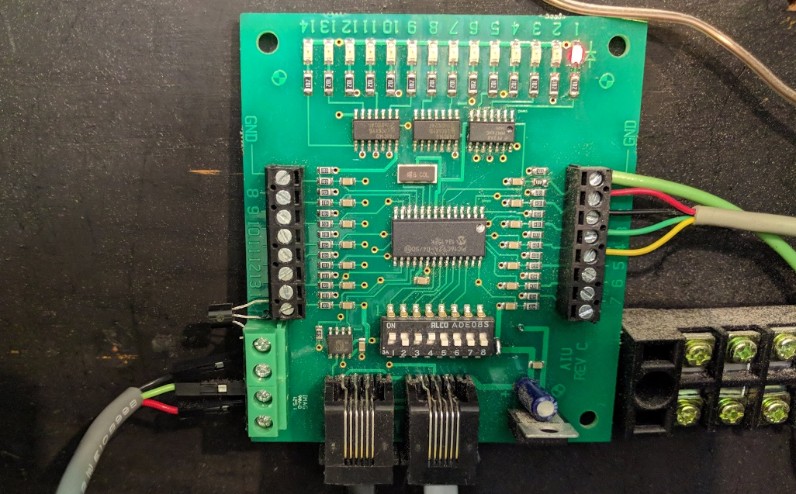

I’ve installed the motion sensor with the AIU:

- Modified the AIU to have 4 terminal outputs.

- The 2N2222 is stuck between terminal pin 14 and one of the outputs (ground).

- The 3 remaining terminal output match the motion sensor pins: ground, signal, 5V.

More technical details can be found on this blog post.

Click here to continue reading...

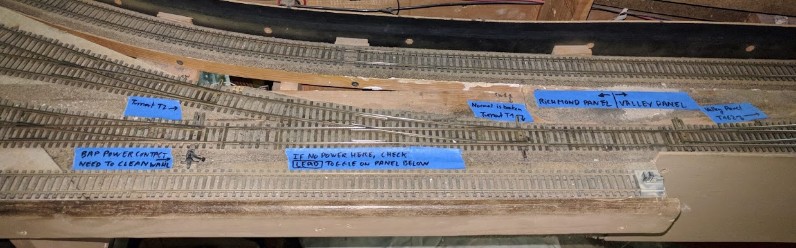

One more thing that happened this week-end is starting to look at the Richmond Yard, the track connecting it to the mainline, and the associated yard panel. As usual on this model railroad, the major issue is a crucial lack of labelling. I’ve started by applying notes with blue painter tape, and I’ll figure out better labels once everything is understood:

Click here to continue reading...

With Jim, we’re trying a new train in the Mainline to replace the Doodlebug. This looks like it should provide some interest to our public:

Leading engine is Santa Fe 804, and this model has some interesting sound. Since it’s running in alternance with the Amtrak Passenger train, I suggested we use these two interesting freight cars. Jim added a nice caboose to complete this train.

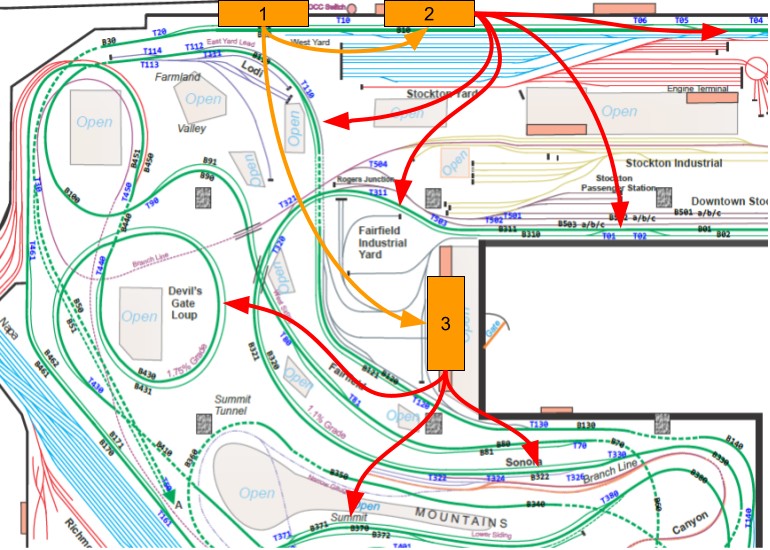

It runs in a back-and-forth shuttle mode on track #2 between the Stockton Station and Sonora. I run it at a conservative speed 16 (on 28) going forward and then speed 12 coming back.

2018-09-08 - RTAC Update

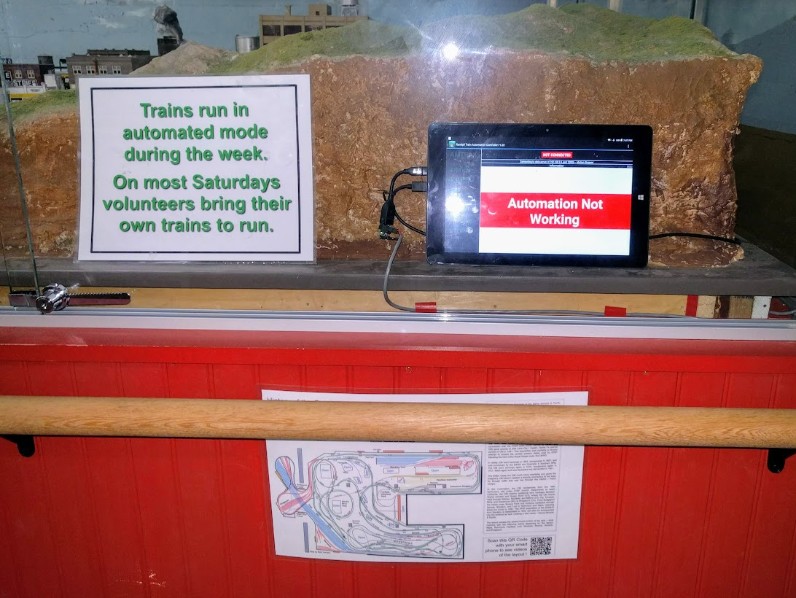

Category RandallRTAC is the software running on the Android tablets. I’ve made some modifications these past two weeks and I just finished enough to deploy the first changes at the museum:

Click here to continue reading...

Here’s an interesting way to not do train automation:

I had been at the museum to examine the RDC in the morning. The passenger train had two coach cars. Jim came by during the afternoon and suddenly ask me if I removed one of the coach cars since the train had now a single car. No I didn’t. How was that even possible?

Click here to continue reading...

Today we’re running something a bit different:

The Doodlebug is back to replace the RDC which is currently dismantled on the bench.

The Amtrak GE unit is back with two coach cars. Jim spend quite some time checking the cars were carefully weighted and made sure they would stay on the track.

2018-08-22 - Something Unexpected

Category RandallThis was rather unexpected:

The passenger automation currently runs with two UP engines. Then once the passenger train goes back to the station, the RDC goes out. Although they use the same track, they shouldn’t be on the same block at once.

Click here to continue reading...

For a change of scenery, today’s Saturday running has the TGV Atlantique in Multiple Units:

The TGV going over a wooden trestle bridge is a contrast that I enjoy every single time:

Click here to continue reading...

Four days ago, a derailment of the Amtrak train occurred. This was left unattended for a while. The end result is that both trucks on one of the Amfleet coaches melted. I didn’t even have a remote idea this was possible. I did not get a chance to see the damage first hand nor how it occured. One possibility I can consider is that there was a short and it lasted long enough to somehow produce heat and melt the trucks.

Photos: J. Evans.

That left me speechless. Not for long though.

Click here to continue reading...

From the always excellent Gurries’ web site:

One thing I have experienced a few times at Randall are unresponsive engines. Luckily it is not a very frequent thing and each time I have seen it only on very specific engines. My first TGV unit using a custom LokSound V3.5 had the issue -- when running it after a while on very busy Saturday ops days, it would sometimes cease to reply. I “fixed” the issue by switching to another decoder, a newer LokSound V4.

However I have seen the same issue with other operators’ engines. Very very specific ones, and luckily not that many. I can think of a handful of cases.

A while ago that made me think whether using “snubbers” (RC filters) would be a possible choice, and if yes, where should they be located. Thus the link to Gurries’ web site above.

Unfortunately, when I read his “ideal bus wiring”, it seems to me that the Randall’s wiring is hitting all the wrong spots.

Click here to continue reading...