The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2020-12-23 - Bridgeport Auto-Reverser for Second Balloon Track

Category RandallI recently installed an auto-reverser on one of the two balloon tracks at Bridgeport, as indicated in the previous Bridgeport post. In between I ordered a second one and today I was going to install it.

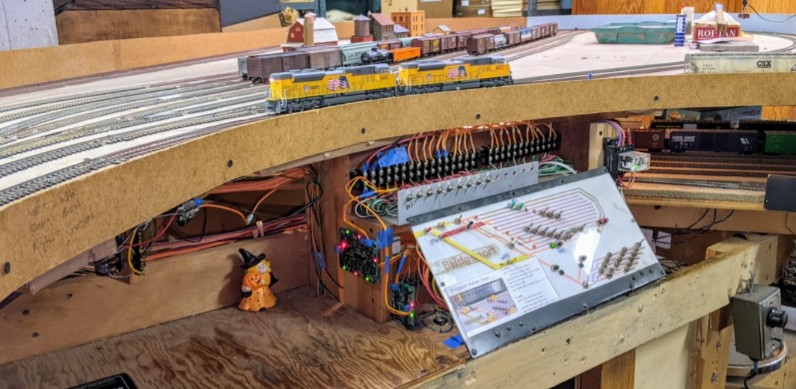

Two engines led by Walthers Mainline UP 8823 enter the outer balloon track at Bridgeport.

For the auto-reversers, I settled on using the Tam Valley Depot Frog Juicer Auto-reverser; I really like them, they work very nicely.

Unfortunately when the order arrived, I had a little surprise:

That is surely no fault of the reseller, Iron Planet Hobbies, as they sent me a package that says “Dual Frog Juicer” alright; except inside we have a Tam Valley Depot “Hex Frog Juicer”! It also happens to be twice the price of a regular Dual frog juicer. I’ve ordered before from Iron Planet Hobbies, they have a good selection, good prices, and have always been neatly reliable. Free plug here, go support them. We need OEMs like Tam Valley Depot and resellers like Iron Planet in this hobby!

So here’s the conundrum… the “Hex” as the name implies has 6 output, and in this case it could serve as an auto-reverser for 3 tracks. On one hand that’s neat as I could cover both balloon tracks on Bridgeport with just the one board. On the other hand, the specs for the Hex Frog Juicer clearly indicate the cut-off point is at 1.7 amps and to not use it with 10 amo boosters (which I believe we have at Randall). Although that’s fine for a frog which has never more than one engine on it at a time, it’s not ideal for an auto-reverser loop track as 2 engines in DCC with sound can trivially reach that limit.

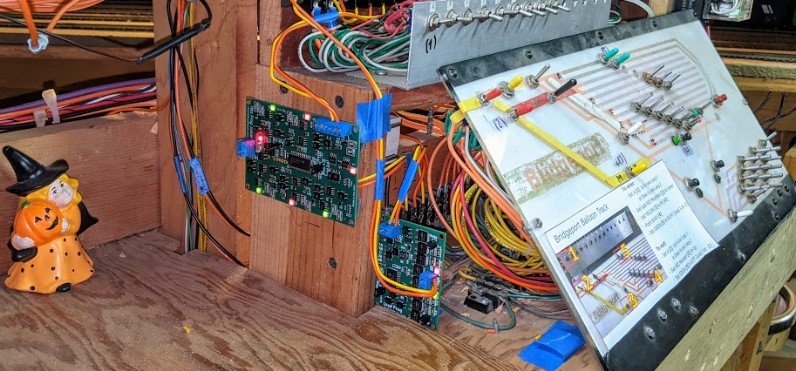

Testing the Hex Frog Juicer (left) and the Dual Frog Juicer (right) on the Bridgeport panel.

Why is that a problem, would you ask? For that, it’s important to understand how these auto-reversers work: they basically detect short circuits. When a balloon track has the wrong polarity, the wheels of the engine basically short the booster’s power supply at the junction, very much like hitting a turnout that is not thrown properly. On a layout like Randall, this triggers the NCE EB1 circuit breakers which just cuts power till the polarity is reversed. The trick with these automatic auto-reversers is that they detect that and fix it in a matter of milliseconds -- the detection and reversal is so fast that engine running and sound are not even affected.

As soon as the Hex Frog Juicer sees more than 1.7 amps being used on the track, it thinks there’s a short and inverts the polarity.

On the Dual Frog Juicer that I used before, there’s a jumper to set that cut-off limit to 4 amps (called the “current setpoint” in the PDF).

A good rule for DCC is to assume that one engine with sound can use up to 1 amp. Operators at Randall typically run a lash-up with two engines, so we can expect to hit that 1.7 amp limit fairly easily. And to be fair, even the Hex Frog Juicer PDF clearly documents it, so it must be a common issue.

Thus before I would return it, I did want to test that theory. The bottom line is that as I guessed, it can’t handle the two engines seen on the picture below. It works fine with one engine on the track, but as soon as I have two engines, it keeps shutting off and trying to reverse polarity. I was able to have it work somewhat by running the engine rather slowly. I’m guessing turning off the sound would have helped too, yet I did not try that. Anyhow, that’s not suitable for our common usage.

For testing, Dual Frog Juicer wired on the inner balloon loop 1, Hex Frog Juicer wired on the outer loop 2,

It was nice to have a chance to try the Hex Frog Juicer. Now I need to get a proper Dual Frog Juicer and install it.

In the meantime, I have the outer loop wired with the Hex Frog Juicer so we’ll just need to run single engines on that balloon track.

The other solution is to keep it and use it for intended original use, to power 6 frogs.

I can’t think of another place on the layout where I would want to power the frogs that way for now, as they are all already covered by the slow-motion turnout switches, and converting them to use the Hex would be actually more work. Maybe I’ll keep it and use it later when I rebuild Fairfield (11 turnouts), or we could try to use it on the Stockton Yard lead A ladder -- by design the Hex Frog Juicer can only power up to 6 frogs, and ideally they need to be close together, so that excludes anything on the mainline.

From a closer look at the Dual Frog Juicer:

- Neatly designed board. Lots of routing to fit all that in a compact form factor.

- PIC16F720.

- 5 pins bottom right, one marked with a triangle, looks like what I expect to be a PIC ICSP (in-component serial programming), to be used with a PICKit3 dev kit.

- 1x AD32 MB6S … Fairchild MB6S bridge rectifier next to the DCC with the clear +/- markings.

- Next to it is a 3-pin component that looks like a voltage regulartor. Can’t quite read the reference.

- 8x D51 356T or 358T WC…likely a dual channel phototransistor optocoupler?

- 8x B32 58 05NG on the output side…likely ON Semi NTD5805N N-channel MOSFETs -- good up to 51 amps!

I’m not sure why there are 8 of each, 4 per frog (I’d have naively expected one comparator per frog + one output mosfet). The Hex Frog Juicer is similar to the Dual one yet lacks the 5805N mosfets on the outputs.

Note: from the ON semi datasheet, I learn that the first code is a code indicating the fabrication place + year. The second code after is the component name.