The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

Time for more maintenance. This time I adjusted the grade crossing light sensitivity with some room lights off, and it seemed to go better. In this case I had the fluorescent lights off, the single center spot on, and the side spots (by the walls) on medium.

More importantly we had an interesting case: a turnout malfunctioned on the Bridgeport lead track.

That seems innocuous except this somehow shorted the B450 block on the mainline (the one that leads to Bridgeport) on the Mountain Panel 2, and it also made blocks B330 and B360 seem occupied on the Mountain Panel 1 -- these two blocks are used by the automation and since the track appeared occupied the automated trains would not start. It did take me some time to figure all that out since I started in reverse (why the blocks seemed occupied) and I had to trace it back to the short on the other panel and then to the Bridgeport lead. I still don’t have a full explanation here. It just doesn’t quite make sense.

Anyhow, this is what I found on the Bridgeport lead:

What’s wrong with the point?

Click here to continue reading...

2021-09-21 - Maintenance

Category RandallYesterday was also time for some regular maintenance.

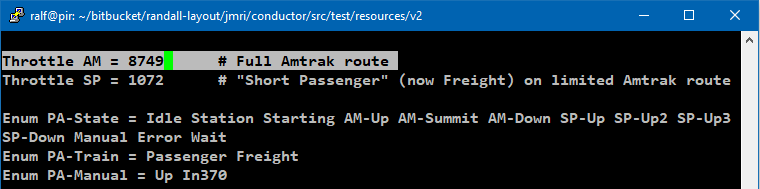

First order of business was to swap the engine for the automated UP passenger train. It has been running with UP 8736 for quite a while, and I swapped it for UP 8749. They are both identical SD70ACe engines, and I had previously programmed them to have identical running characteristics, so it was a quick one-line change in the automation computer’s event script.

Then I had been told the grade crossing bell was ringing all the time with no trains, so I spent quite some time adjusting it. One of the sensors is way more sensitive than the others. I readjusted them all. Unfortunately I’m told today that the bell was again ringing for almost 20 minutes when the layout was turned on. I had noticed that before -- when we turn everything on in the room, the lights are not as bright and they take time to warm up. And that can be enough to trip the grade crossing light sensors. Ideally I’d have to adjust the sensor right when the lights are turned on in the morning.

So I need to adjust the grade crossing sensors again. I’ll see if I can reduce the dimmable spots or turn off some lights to reproduce that “warming up” state from the morning.

2021-09-20 - Train Vision

Category RandallThe “Train Vision” project: One part is my custom Vision software that runs on a laptop, displaying pre-recorded videos fullscreen. A second part are cameras located on the layout display live trains as they go by. When the live trains are visible, motion detection kicks in and the display changes from fullscreen to a 4-video quadrant with one view being the recorded video and the 3 other being the 3 live cameras.

I’ve spent the first half of the year reworking the Vision software from the prototype I did last year, and it’s now good enough to install it at the museum. It’s not perfect, yet we need to see it in real condition to adjust it.

The display is a 17-inch laptop. A lot of time was spent to make sure it would work as automatically as possible. It is now configured to start when the power to the layout is turned on, and it shuts off automatically with the layout power. It auto-boots Linux and my dedicated Vision program. The museum staff will not have to interact with the laptop -- no need to manually turn it on or off like they do with some other exhibits.

I quickly placed the 3 live cameras on the layout by the Fairfield passenger station. That’s temporary.

Click here to continue reading...

Affected |

Turnout T450 to Bridgeport. |

Description |

Turnout motor overloads the entire turnout power supply. |

Summary Fix |

Replace the Fulgurex. |

Description of Issue

The Bridgeport turnout needed fixing, and it is now fully functional again.

It uses a Fulgurex turnout, and recently this one had started shorting the entire turnout power supply intermittently.

This is a Fulgurex slow-motion motor. Connections have two wires for turnout power, and two sets of contacts (three wires each) that are commutated based on the position of the switch:

Description of Fix

And here it is after the fix, when testing it:

Click here to continue reading...

Lighting on the Stockton side:

The Fairfield main street with street lighting on, and the illuminated McDonalds:

Click here to continue reading...

I’ve been trying to update my documentation on the Building Lighting panel on the layout.

As a “recap of the previous episode”, under the Valley Panel 1 is located a row of toggles for “Scenic Lighting”:

Besides a few numbers (1 to 29), there’s not much indication on what these do.

Looking at my old emails, back in 2015-02-09 (before the GGMRC club donated the club to the museum in December 2015), I tried to understand this panel to light up the Fairfield town. Back then no lights were working and I “fixed” the power supply by replacing the fuse -- after finding they had the appropriate fuses behind the Stockton Yard panel.

From my notes, the fuse for the bulky 1997 power supply is a “5A 250V 313 Slo-Blow in a 31.75 mm (1 1/4") glass cartridge”. Here’s a mouser link for that kind of fuse.

So let’s try to decode all this. First, which toggles do produce any kind of lighting today? Allen and I could only find these below illuminating anything on the layout:

Click here to continue reading...

There’s been a multiplication of small-to-medium tasks recently, so it’s worth making an inventory of what needs to be done on the layout. These are more or less in the order I plan to address them.

Task |

Impact |

Work Load |

|

Building Lighting: Install / power Jacker Jack sign |

Want |

High |

Medium |

“Train Motion” Project (cameras display for public, ongoing) |

Want |

High |

Very High |

Adjust Grade crossing lights at Fairfield Station |

Need |

High |

Low |

Bridgeport ballon track: Install the new DCC Auto-Reverser |

Need |

Medium |

Low |

Bridgeport turnout: Replace the Fulgurex turnout |

Need |

Medium |

High |

B91 Siding: Wall sign & turnout LED status. |

Need |

Medium |

Medium |

Fix the Fairfield-Lodi approach Status: Replacing turnout motor for T905 |

Need |

Medium |

High |

Fixing dead spot at Sultan |

Need |

Medium |

High |

Automation of Fairfield area |

Want |

High |

Very High |

As usual tasks fall into two categories depending on their “impact”, meaning how visible a task is. “High impact” tasks have the most impact on the layout as a museum exhibit, from a public/visitor point of view -- these can be either scenery improvement, automation improvement, or anything that enhances running for the Saturday Operators and public view.

Click here to continue reading...

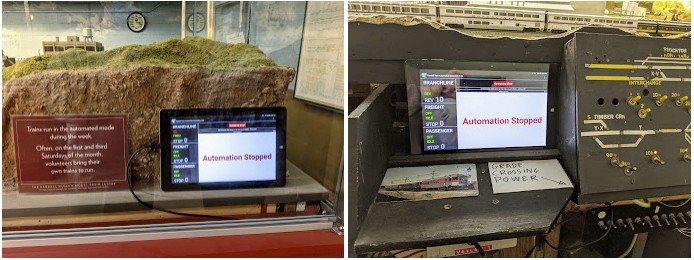

I reinstalled the tablet displays on the layout, preparing for an eventual reopening of the museum:

Allen got a “Cracker Jack” illuminated HO-sized billboard, so we’re trying it out to see where it would look nice on the layout; here’s Allen first idea and it seems like a good option:

(Edit: And here’s an update on how I think these work and how I managed to ruin the electronics for that one by using the wrong voltage to power it, so now I’ve ordered a full replacement and I’m waiting for it; they also sell replacement controllers.)

I think we should power it from the building lighting circuits (see below). So I had to dig a bit into it. The building lights are controlled by a row of unlabelled toggles under the Valley panel:

Click here to continue reading...

Today we are working on the siding B91, located between turnouts T80 and T90. It has been unused for quite a while. Turnouts T80 and T90 still work fine. After carefully scrubbing the track on the siding to clean it, it worked fairly well.

A steam train enters the siding at T90.

On the other side at T80, we have 3 electromagnet uncouplers:

Click here to continue reading...

Affected |

Mainline block B320 (outside) from Stockton Station to Sonora. |

Description |

Dead spot after the cantilever signal bridge. |

Summary Fix |

Broken solder on outside rail. |

Description of Issue

Today we’re fixing a dead spot that appeared out of the blue on the mainline, in the middle of block B320, right were engine 1201 is on this picture:

Initial inspection shows there’s nothing interesting there. It’s the middle of the block. Closer inspection gives a different story; one may even say this spot had a story to tell:

Click here to continue reading...