The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2020-09-27 - State of Projects

Category RandallTime for a little recap on pending projects, and a vague attempt at prioritizing them. This is an update for my post [2020-02-29 - Pending Work on the Layout]. Not going to make a fancy table this time, yet the same categorization as before is relevant, namely impact on layout running, impact on public viewing, and time/complexity.

The slight difference is that right now I am not prioritizing immediate public viewing since the museum is still closed till further notice. However we have weekly running to keep the track clean, so even if automation is off for a little bit, the layout must be running.

Currently, these are the projects I expect to be working on, in this order:

- ESP32-CAM for Grade Crossing.

- Impact: Immediate for running / public.

- Complexity: High. Lots of uncertainties. Time consuming R&D.

- Really needs an initial prototype. It’s a two-phase project: validate the concept, then implement the real one. Don’t expect something right away -- thus avoid advertising it before it is known to be functional.

- Power block for Stockton station.

- Impact: None for running, none visible for public automation.

- Complexity: Low. Just time consuming pulling wires.

- Will open the door for adding block sensors in the Stockton yard and providing more automation.

- This may help with the stopped automation train being affected by DCC commands in Stockton Yard.

- Finish 3rd turnout indicator in the Napa approach.

- Impact: Medium-useful for running

- Complexity: Low.

- Complete Conductor 2 software.

- Impact: None for running, none visible for public automation.

- Complexity: High. Long term.

- Will open the door for more automation down the road. I have a partial early prototype, which I never fully finished fletching out. There are still some open questions as to whether the new design can do what I need, then it needs to be fully implemented.

As usual, it needs to be said this list is dynamic. I will adjust my priorities as I see fit. Any maintenance repairs on the layout take priority.

There are other pending projects, which I honestly do not see working myself on in a reasonable time frame:

Click here to continue reading...

Jim is getting a new crossing signal for the Fairfield station:

This is to replace the previous version I did:

A bit of history on what happened to the signal that can be seen in the video, and a personal rant:

The old signal and its controller were removed by Marvin Chow when the GGRMC closed in 2015 -- from what I understand, he had donated such a signal a decade or so ago before leaving the club; the signal had failed and I had replaced it, and then he removed the one I had installed without asking anyone, claiming it was his and proceeded to donate it again to the Carquinez MRR. Rather pathetic to even claim to donate something and then take it back with the typical sleazy excuse of “well I didn’t really donate it, it was a loan”... sure. Whatever.

Anyhow, Jim got a new crossing signal, and we need to power it. Last time I connected it to a LogicRail Tech Grade Crossing Pro and its associated Bell sound module. These are the elements that were taken out unceremoniously. I could reuse the same -- they work well, within their limitations, or I could try to make an Arduino version and experiment in the process.

Click here to continue reading...

Here’s what’s been keeping me busy for the past two weeks at home:

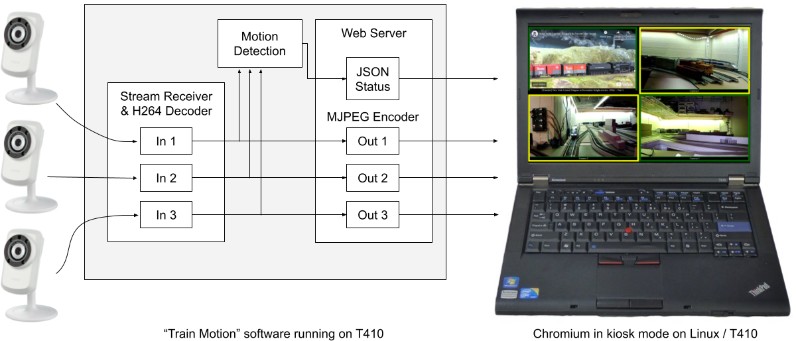

“Vision” a.k.a. Train Motion (source, MIT license) runs full screen on a laptop and plays a series of Youtube videos of the model railroad in a loop. Three cameras point to the layout and, when activity is detected on these cameras, the view changes to a matrix displaying both the Youtube video as well as the three layout cameras, showing whatever train is going by. Once the train is gone, the Youtube video plays full screen again.

Visitors get to enjoy an interactive display -- either a curated series of pre-recorded videos, or live action of the trains running on the model railroad.

Here is a video demonstration of “Train Motion” in action at Randall:

Presentation video (Subtitles are available, use the [CC] button on the video to see them).

Click here to continue reading...

As indicated in the latest update, I added some LEDs indicating when the turnouts are left thrown on the mainline. After experimenting with some LEDs at home, I’m using a single red LED that is on when the turnouts are thrown:

Eventually I would like to have a little dwarf signal there instead of just a LED protruding from the scenery. I was hoping I could 3D print some at work yet I still don’t have access to the 3D printers due to the lockdown -- there are some dwarf signals available to buy online of course, yet that’s one project where printing my own would be a fun task. I’m not in any hurry and I may be able to access the 3D printers by the time the museum reopens anyway.

Both T151 and T162 have been equipped. Eventually I’ll add one for T150 too. I cannot force the Saturday Operators to pay attention to the signals, yet at least that’s a spot where I can make the layout usage a tiny bit less error prone.

2020-05-02 - Ongoing Maintenance

Category RandallAlthough the museum is still closed, the situation here is somewhat relaxing; consequently Jim and I ventured to the museum to do some much needed track cleaning -- our concern was that many months of non-usage would make the track harder to clean, and we believe some regular maintenance will help avoid downtimes when it is time to re-open. Luckily we completed that task without any difficulties.

I have using this workflow for light track cleaning with good success:

Click here to continue reading...

A Shelter-in-Place Order was issued Monday March 16, 2020 for the City and County of San Francisco and other Bay area counties and will remain in effect until April 7. The Randall Museum is currently closed to the public and is in between used for the Emergency Child Care Center effort organized by the city.

More information here:

- https://www.randallmuseum.org/randall-museum-update-3-18-2020-regarding-shelter-in-place/

- https://sfmayor.org/article/san-francisco-issues-new-public-health-order-requiring-residents-stay-home-except-essential

- https://sf.gov/information/san-francisco-converts-rec-facilities-emergency-child-care-centers

- https://sf.gov/topics/coronavirus-covid-19

As a volunteer, my presence there is non essential. I have a lot of work pending on the layout that will just have to wait.

From a technical point of view, that means the layout will not run for many weeks in a row. That may be a problem as tracks oxidize and gather dust when there are no trains running for a long period of time. Thus I fully expect we (and by “we” I mean essentially just me alone) will have to spend quite some time going in there and manually scrub the track to make sure trains still run smoothly. Some folks naively think it’s as easy as just running a track cleaning car, and my experience is that nothing beats actual elbow grease to scrub the track in the accessible areas.

I could ask the museum staff to run the trains once a week. I’m going to venture that they have reduced staff numbers and more urgents things to focus on. And even that would just induce a different issue, namely that all that dust accumulates over time as gunk on the train wheels. We need to clean them monthly or it can become significant enough to derail them.

Affected |

Turnout T151 leading to Napa. |

Description |

Point not moving. |

Summary Fix |

Replace Fulgurex. |

Description of Issue

The turnout T151 has been repaired:

These are Fulgurex slow-motion turnout motors. They are mounted on the layout using an aluminum bracket for support and alignment, with wires to switch the polarity of the frogs. Very neat job done eons ago:

The symptom was the point not moving, even though the Fulgurex motor had power. This one is on the cross-over that goes from the mainline to the Napa / Richmond yard access:

Click here to continue reading...

Just a little brainstorming session here. One thing I’d like to add to the automation is an automated single loop run; that is place an engine which is not under normal automation, and let the computer run it for one loop, without deactivating the automation. It would have to coordinate between the two, to make sure the transient engine can only run on the shared mainline when available.

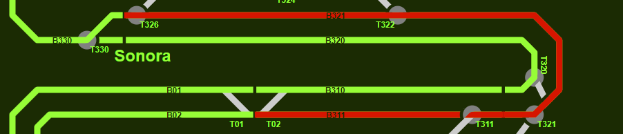

The JMRI program has block detection for both blocks B310 and B311. B310 is the “first track” and B311 is the “second track”, and the blocks start in front of the Stockton Station.

We have the Automated Freight Train parked and waiting on B311. Saturday Operators use the B310 track to run on the mainline.

In this example, I place my TGV #537 on the outside mainline track and I want it to run. Today, we have some provision for that, using the “manual” mode. It works by bringing a train to block B320 and waiting for both automated mainline trains to go in wait/idle mode. The automation changes to “manual” mode, aligns the Sonora turnout, and it is up to the operator to start and run its train. Once a train reaches Summit block B370 and then clears it by entering B380, it releases the manual mode, and automation can start again.

What I want is the same, except the run would be automated.

I can see this working in a full automated fashion as such:

Click here to continue reading...

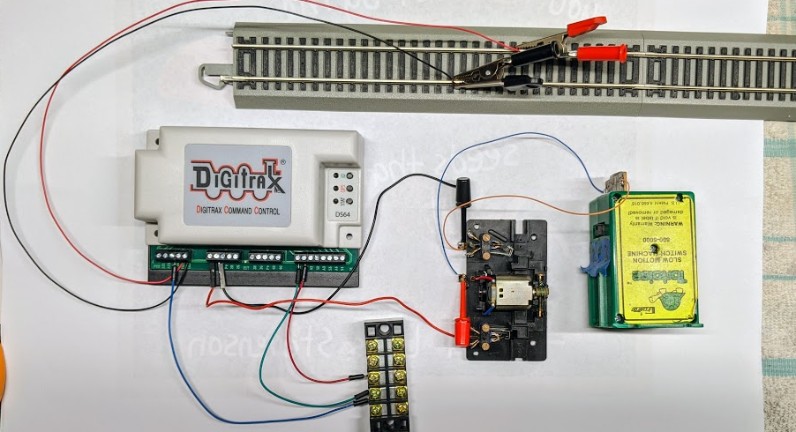

Connecting a Digitrax DS64 to control both a Tortoise and a Fulgurex via DCC:

According to Digitrax tech note KB273, this configuration cannot be used as the Fulgurex takes “about 400 mA” when running, which exceeds the specifications of the Digitrax DS64 as well as ones of the NCE Switch-8.

Fulgurex and NCE Switch-8: Does not work together. I do confirm that the NCE Switch-8 cannot drive a Fulgurex directly (although it works when using the NCE Relay Board to do so).

Fulgurex and Digitrax DS64: Results are mixed. In a standalone test, I had no problem driving a Fulgurex directly with a Digitrax DS64. In situ at the museum I had one success case and one failure case. What happens is that the Fulgurex does take a lot of power, around 200 mA with a lot of variation. This exceeds the specs of the DS64. Looking at voltage, I noticed it was not symmetrical: Full 12 V voltage driving the Fulgurex in one direction but voltage dropping to 3~5~8 V when driving it in the other direction. This means we’re exceeding the current capability of the DS64 output and thus voltage drop. If some Fulgurex has a low enough impedance, it may work. If it has a higher impedance, it does not.

Let’s see how to use this. Instructions follow, let’s start with the documentation:

Click here to continue reading...

Trying to strive for a balance between work I want to do on the layout versus things I believe need to be done, coupled with their direct impact (either for operators or automation) and work complexity.

Here’s a current list:

Task |

Impact |

Work Load |

|

Stockton Station dedicated Circuit Breaker |

Need |

Medium |

Low |

Mainline turnouts for Napa approach |

Need |

High |

Medium |

Fixing dead spot at Sultan |

Need |

Medium |

Medium |

Layout “cab ride” Cameras & Display for Public |

Want |

High |

High |

Computer monitoring of all Circuit Breakers |

Want |

Medium |

High |

Finish DCC control Mountain Turnout Panel |

Need |

Low |

High |

DCC control Stockton Turnout panel |

Need |

Low |

High |

DCC block detection on Valley panels 1 & 2 |

Need |

Low |

High |

DCC block detection on Mountain panel 1 |

Need |

Low |

High |

Automation of Fairfield area |

Want |

High |

Very High |

Automation software “Conductor” v2 |

Want |

High |

Very High |

There are more tasks on my list; these are all I’d consider important for now.

Click here to continue reading...