The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2021-11-15 - Randall Repairs: Block B321 / Turnout T322

Category RandallAffected |

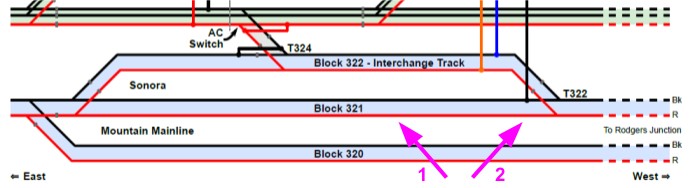

Mainline B321 close to Turnout T322. |

Description |

Dead spot on Mainline B321. |

Summary Fix |

Fix bad track joiner. |

Description of Issue

As explained earlier, we’ve been having issues with the train stopping on a dead spot on the mainline block B321, just after the Branchline turnout T322. I posited the issue was a broken solder joint, and it was indeed the case. A repair has been made -- actually two of them --, we’ll see if that holds.

On the track schematics, repairs were performed at the approximate locations shown below, on the red-side rail.

Trains used to stop dead in that area recently, intermittently. Typically that’s due to a solder joint that is broken and now makes a bad contact. As the track shrinks or expands with humidity, temperature, and the weight of the rolling stock, contact can appear or vanish during the day. The test was simple: with the train dead at that spot, just putting some slight pressure on the track was enough to power the train again. Problem is, that track has been naturally weathered by decades of usage, and it’s nearly impossible to know where the solder joints are, or for what. There can be many, from track feeders, to rail jointers. Not to mention the voluntary block isolation gaps that I need to preserve. Due to the lack of documentation, it means that when I find a gap (or a broken rail that looks like a gap), I don’t really know if it’s on purpose or not.

Description of Fix

First repair at spot #1 was done somewhere near the middle of the block. There is a track feeder under the layout going to both the black and red rail. It’s worth pointing two important details at this point:

- The track rail is quite thin. I don’t know what code rail was used there, or whether this is due to decades of model railroaders scrubbing the track with their aggressive Bright Boy cleaners…

- The track rail is also not held in place by the track ties. I can flex and push the rail inwards on both sides of the track.

That innocent little solder took me about an hour to do, because the thing is at arm’s length. It also means I can’t really see what I’m doing because it’s too far for me to see it clearly. Cue in the smartphone to take pictures after each attempt, in order to see if I may have done it right. Eventually I believe I got this, and I could feel the track feeder move with the rail when I was flexing it.

Although that was an improvement, it wasn’t enough and the train was still dead in some cases. So back to “close” inspection of the track, from far away. That let me to spot #2 next to the T322 turnout. Can you see the issue in the following picture? I’ll give you a hint, it’s next to the flat car with the cat:

Of course you can’t see it. See what I mean by having to work at arm’s length? Here’s the zoom on the issue:

There’s a solder (without any jointer) between two rails. With the metal pliers I was able to confirm bridging that gap would solve the dead spot. And here we are after a while longer:

So I think I got this fixed for now. The astute reader will note that there is no rail joiner here. There’s no relief in case the metal rail needs to expand or shrink with the inevitable temperature changes during the year.

Fix time: 3 hours.