The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2022-02-09 - Turnout Frog Power Routing

Category RandallNow for something a bit different… understanding power routing on turnouts as used at Randall on the mainline.

This replies to a question I had recently, and eventually I’ll add it to the Randall Layout documentation because it’s good for future reference. Once again I was tempted to write here an explanation of why turnouts are wired the way they are, yet that would be long and convoluted. For that, I’ll just refer to the excellent material at https://dccwiki.com/Turnout which is complete with detailed schematics and presents the various ways a turnout can be wired.

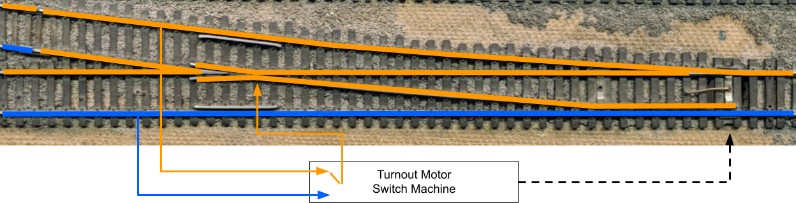

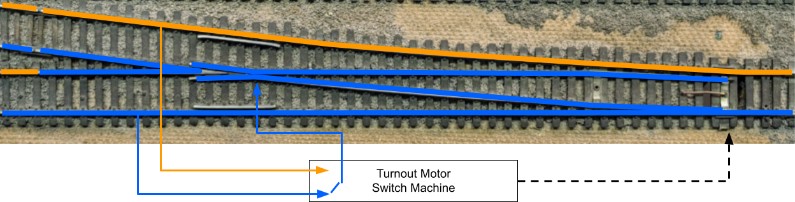

For our mainline turnouts, here’s a concrete example by taking an overhead shot of Turnout T05 and coloring the rails A and B and all the parts which are electrified the same way:

Turnout straight/normal.

Turnout thrown/diverging.

Non-isolating power routing turnout:

For reference, this style is called a Non-Isolating Power Routing Turnout: the entirety of the frog and the closure rails are one contiguous section and are all powered depending on the position of the turnout. Two wires bring power from both rails A and B into the switch machine and a contact moves to select power from either rail A or B and powers the frog and the connected closure rails accordingly.

I want to mention that this style of turnout seems, to me, typical of an older DC installation like Randall is. For a modern layout, I’d expect so-called “DCC friendly” turnouts where the frog power routing is handled differently.

The obvious issue with the arrangement as used as Randall is the proximity of a switch rail to a stock rail of opposite polarity. It’s easy for an engine with wheels out of gauge to bridge that gap. In practice that’s not an issue I remember us having at Randall. What I have seen however is a few instances of broken switch rails or broken switch rod -- in that case the switch rail stayed in contact with the outside stock rail instead of moving away and changed polarity, creating a short. This can also happen when the switch machine rod is not tuned properly and there’s a delay with the switch rail moving after the switch machine has changed the frog polarity. We definitely have these issues on some turnouts, which is easy to notice as there’s a brief short which happens when changing a turnout toggle, yet there’s no issue when a train enters the layout.

A common issue I’ve seen at Randall are the contacts on the Fulgurex either breaking or not making a good connection. In some cases, they exhibited some resistance which means that when measured without load, the frog had the correct voltage but as soon as an engine ran over it and started using power, the resistance made the voltage drop and the engine couldn’t run. Now to be fair, these Fulgurex were likely installed in the 70s and nearly 50 years of continued service is quite remarkable, so let’s give them that credit. Typically today we replace such switch machines by Circuitron Tortoises, yet who knows how Tortoises will fare in 50 years (I bet just as good as the Fulgurex, they are both sturdy designs).

For the “frog resistance” problem, my typical test is to take a voltmeter and measure the voltage drop when a train enters the frog/closure rail. I realized another way to do it would be to measure the resistance between the frog and the same closure rail by inserting some insulation such as a thin piece of plastic before throwing the turnout, and the measure can only be done when there is no power on the track -- which is as easy as turning the corresponding block off on the panel.

Finally another issue I noticed is that we have engines stop-and-go when they cross a power district boundary. All the DCC boosters do not have the exact same voltage level, and there’s a lot of variation in power feed length & resistance. Some engines definitely don’t care, and some others hesitate on these boundaries, so clearly there’s some decoder variance right there. That’s a phenomenon that I fail to understand properly.

Where does the power come from?

That’s one issue I encounter often when trying to diagnose problems at Randall. For example the latest issue with turnout T161 turned out to be due to the way the turnout was getting its power from the adjacent block.

Let’s take that example as it seems typical of what I’ve seen on various places on the mainline at Randall (yards are different): we have a mostly single-track mainline with sidings from time to time.

- When the mainline splits into a siding, power to the turnout comes from the single-track block, and the turnout is electrically isolated (rail gaps) from the siding blocks.

- When the sidings join into a single-track block, the turnout power comes from the single-track block, and the turnout is electrically isolated (rail gaps) from the siding blocks.

To be honest, I have not looked at all mainline turnouts so I’ll add a disclaimer that this may or may not be true in all cases. It was in most instances I looked at.

If we look back at the aforementioned T161 turnout, we have a situation like this:

In this case, power flows this ways:

- Turnout stock rails are connected to the B161 rails via rail joiners.

- Turnout frog takes power from the stock rails and feeds it to the frog.

- Turnout stock rails are isolated from the B170/B171 siding via gaps in the track.

Thus failure to have power on the frog can also come from the turnout not correctly “grabbing” power from the adjacent block -- in the case of T161, the joiners were not making a consistent electrical connection.

One more complexity we have at Randall is that this is an old common-rail DC layout. Which means in some places, the “common” rail is continuous from one side of the turnout to the other side, and only the other rail is isolated. However in other places, both rails are isolated. Often this corresponds to power district boundaries, but not always. In this case, both blocks 161 and 171 are powered from the Valley Panel power district: