The Randall Museum in San Francisco hosts a large HO-scale model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall Museum Model Railroad and I maintain a separate tech blog for all my electronics & software not directly related to Randall.

The Rapido RDC SP 10 is back on the branchline!

But first, this happened:

What you’re looking at is the Rapido RDC getting a speaker change. The astute reader will immediately recognize this is in fact the Rapido RDC Santa Fe 192 in that picture, right? ;-) Just kidding, of course you can tell by the baggage area without the passenger seats. The three Rapido RDC engines have basically the same internals, which is very sensible, and I’m fixing the 3 of them at the same time.

Click here to continue reading...

Affected |

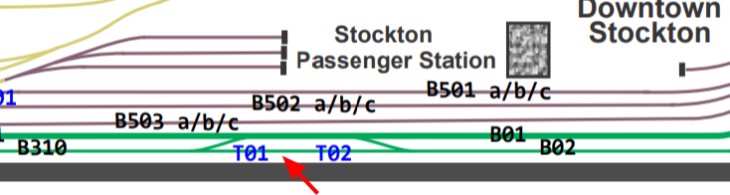

B310-B02 between T01 and T02 in front of Stockton Station. |

Description |

Intermittent dead spot on mainline. |

Summary Fix |

Fix bad track joiner. |

Description of Issue

We've been having an intermittent dead spot on the mainline on block B310/B02, right between T01 and T02 in front of Stockton Station.

Location on the layout track map.

The dead spot is on the “bottom” section of the T01/T02 crossover. Depending on how the turnouts are thrown, this may be contiguous with either B310 to the left, or B02 to the right. In the default normal position of the turnouts, the segment appears to be powered by B310.

It took me about forever to find the spot because each time it was reported, by the time I’d get to the museum the thing would be working again. And due to this, it had all the hallmarks of a broken solder -- a minor crack in a solder that makes or breaks continuity contact based on rail/wood expansion due to temperature or humidity. I carefully examined the track inch by inch in that area and could not notice anything.

Finally today it happened when I was there and I was able to spot the issue:

What, you can’t spot it? OK let’s try to zoom in:

Click here to continue reading...

2023-01-01 - Happy New Year

Category RandallHappy New Year 2023 from the Randall Museum Model Railroad team.

I stopped by the museum yesterday to put our make-shift Polar Express back on automation:

NYC #5278, an Alco “Hudson” 4-6-4, is our lead engine in this operation. This is a great and reliable engine that I have successfully used in automation before. Since I had used that engine 3 years for the same role, the automation change was fairly trivial, consisting mostly of reusing my old Conductor parameters with minimal change to the timings.

This year, the train has a nice Hershey freight car and the traditional Lionel HO Polar Express cars. And let’s not dismiss the inkjet-printed labels that makes this a true Polar Express 🤣.

Video at 11.

The saga with the new Walthers Mainline SD70ACe comes to a very satisfactory end (*): I got the engines back from Walthers. From what I can tell, their support team did exactly what they said they would do, namely change the firmware in the ESU Loksound Essentials decoders. That has totally fixed the running issues. I spent some time this week-end preparing them. They are now ready to be used as replacements for automation.

I’d like to thank all the support team at both Trainworld and Walthers who have been very friendly and helpful in resolving this matter.

(* well not really… because these engines did not last long. They stopped working for other reasons soon enough… you can read more about the Walthers Saga Here)

Affected |

Turnout T111 (after Fairfield station, arriving at Lodi). |

Description |

Specific steam engines stop-and-go on the turnout. |

Summary Fix |

Power the switch rail. |

Description of Issue

We’ve had some specific steam engines derail on Turnout T111 in the past. In the last repair attempt, it was identified the switch rails were loose because there is no turnout throw rod at all. Previously the point rails were spiked, then glued, and that addressed some of the issues for a while.

However most BLI steam engines still stop-and-go on that turnout. An annoying feature of the BLI engines is that they stop when they lose power (ok, that’s understandable) but then they speed up as soon as they cross the dead spot. When doing so, the engines typically have a jerking motion that either derails the steam engines complicated wheelsets, or derails the attached cars, or both.

Click here to continue reading...

Once I was done cleaning the track, I started looking at the new Walthers SD70ACe UP engines I got for the automation. They need a bit of break in before I put them on automation.

Out of the box, I was disappointed to see both engines were lacking the nose headlight & number plates. These were in the box. One of the snowplows was also off. I’ll need to glue them both back correctly -- the last thing I want is for a loose part to come off when running in automation.

UP 8312 and UP 8330 came with a snowplow and the number plates fallen in the box.

It became quickly clear there were a number of issues with these engines.

I wrote a full description of the Walthers Mainline SD70ACe issues on the other blog.

I was cleaning the balloon track on the Napa yard this morning, and realized the “DCC Dead Spot Detection Car” I made was very useful: the LEDs come on or off when the track has no conductivity. When the train runs, they sort of “blink”, and that can give us a real sense of how dirty the track is.

I tried a few variations on the train composition. What works best for normal cleaning is:

- Roller car goes first,

- Followed by engine,

- Then the DCC detection car,

- Finally one or two pad cars.

When the track is really dirty, both the roller car and the pad car go in front of the engine.

To clean tracks that haven't been cleaned in years, I typically use several freight cars as buffers between the cleaning cars and the engine, and I try to even avoid the engine getting on the track to clean if possible.

I’ve noticed a couple times in the last few weeks that the automated Branchline train did not run, yet then it inexplicably started working fine the next day. Normally when the automation stops, it’s due to the train having derailed, which is not a situation that fixes itself automagically.

Of course, then I show up the day after at the layout and things work just fine, so it makes it hard to guess where the failure was. Today I noticed that it was one of these days where the branchline automation was not running. And since I was at the museum, I took a look and started with the silent branchline train. Was the engine derailed? Nope. Was it responding to DCC commands? Nope. Huh, wait, is there power to the track? Nope. Aha, that’s our problem!

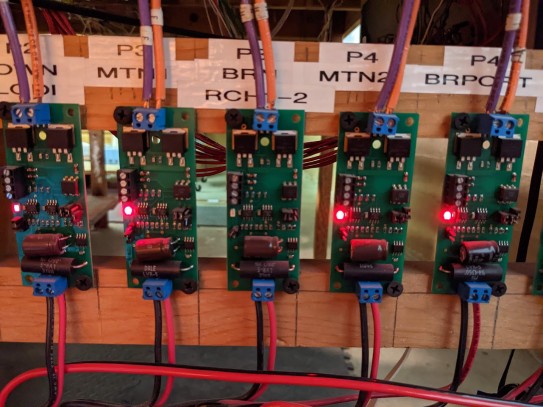

A quick look at the NCE EB1 circuit breakers, and it’s obvious something is wrong:

“P3 BRN RCHM-2” is the sweet designation of the EB1 that controls the Branchline power district. That LED being off is a problem. And measuring it, we have ~13.5V DCC on the input and nothing on the output. So that’s the likely culprit.

I don’t really have a spare EB1 right now because, duh I used them all. But that’s ok, I can borrow the one from Fairfield which is not currently being used. After the annoying task of trying to fit the obviously too large gauge wires in the obviously too small EB1 terminals, I got the thing working in a short time:

Click here to continue reading...

2022-09-19 - Automation Updates

Category RandallThe automation runs 7 hours a day, 5 days a week. That's a lot of runtime for HO train engines which are not designed to run that much in their entire lifetime.

Consequently, for each mainline automated train, I have 2 similar engines with the goal of swapping them on a regular basis. I've done the UP engine a few times yet I have not rotated the Freight train engines in a while, and I finally got around to it today:

NS 1072 Heritage “Illinois Terminal” is back on Freight automation.

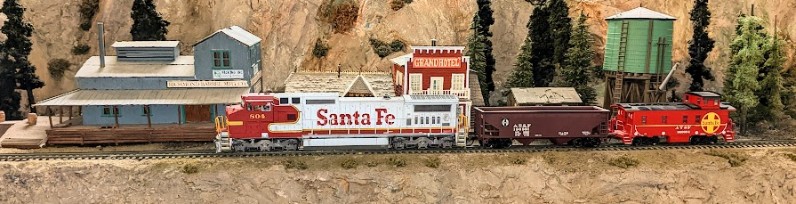

On the Branchline side, Santa Fe 804 has been behaving neatly and I just added a car and a caboose to it:

I'll need to carefully monitor that for the next few days to ensure this combo does not derail. The branch line track can be very finicky in a couple of specific places.