The Randall Museum in San Francisco hosts a large HO-scale model model railroad. Created by the Golden Gate Model Railroad Club starting in 1961, the layout was donated to the Museum in 2015. Since then I have started automatizing trains running on the layout. I am also the model railroad maintainer. This blog describes various updates on the Randall project and I maintain a separate blog for all my electronics not directly related to Randall.

2024-12-16 - Ambiance

Category RandallI’ve just installed “Ambiance” on the layout, a LED fairy light string which is controlled by the train automation computer:

I’ve been working on that little project for a while. It is built around an ESP32 embedded controller running a custom software. The automation computer can send configurable light patterns and animation to the controller, which in turns controls the lights.

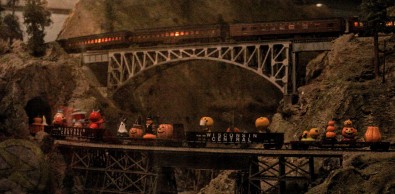

The lights will vary depending on the season. For example right now I have a simple green/red pattern, whilst around Halloween I will have a yellow/orange pattern:

Click here to continue reading...

SP X1225 just arrived in town, with a selection of adequately themed freight cars:

The engine and the caboose were custom painted by Steve B. Thank you for your contribution!

I was told yesterday that the turnouts in Napa Yard were inoperative. Now, that’s not a huge shock since last week I worked on the Richmond Panel and disconnected a couple unused DC track power leads. It would not be the first time that we find some totally unrelated connection between distant places on the layout.

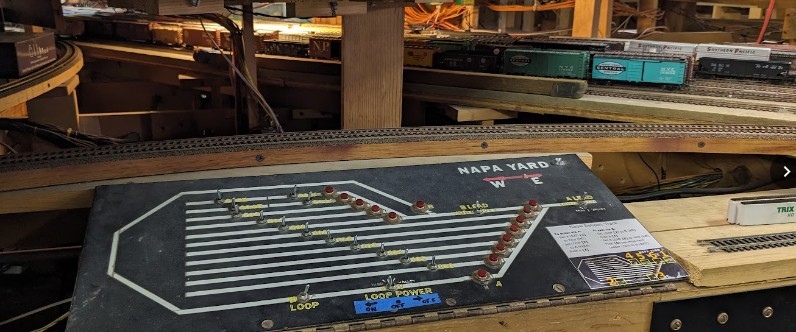

So let’s look at the Napa Yard:

Here’s what the panel looks like when we open it:

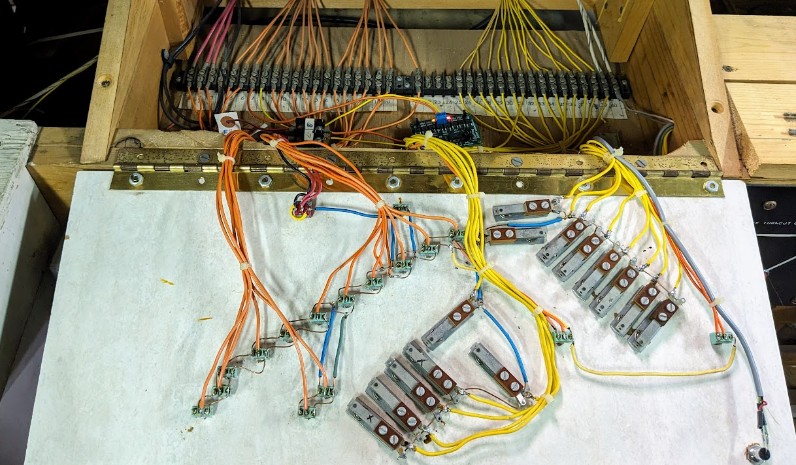

Upfront I can notice that the track power (orange wires) are separate from the turnout power (yellow wires). This is actually as it should be. So now “all” we have to do is follow the turnout wires. They are conveniently located under the layout and a bunch of things have been piled in front of them over the years, making access impossible. So first, I spent 10 minutes removing a cabinet, and before I could even do that I had to remove a couple unused DC equipment components:

Click here to continue reading...

So here’s a funny one: each time the Saturday operators use the Richmond Yard, the Mainline automation totally goes berserk and fails. Upon examining the logs from the automation computer, I noticed that some of the mountain blocks were seen as active even though there were no trains in the mountain. What’s going on here?

As a reminder: the automation uses current-sensing block sensors. A block is deemed occupied by a train if there is current flowing through that block. The sensors are located on the mountain panel, one per block.

The Richmond Yard and its panel. Mountain division is in the background.

They are not far away yet both should be totally isolated from each other.

This happened twice, and we narrowed it down to only two of the mountain blocks becoming active -- blocks B340 and B360 seen as active -- these are the ramp up and the curve before Summit on the Mountain. Basically the automation thinks there are trains at odd places and goes into error mode. Hilarity ensues. This happens when we have any train consuming power on the Richmond Yard. It’s enough for the trains to be sitting in the yard and not moving.

The yard panel has a power selector for “Cab 1”, “Cab 2”, and “Valley” DC input power. That’s a remnant of the DC power scheme of the layout and we don’t use anything but “Cab 1” for the DCC. To try to isolate things, in the terminal block behind the panel, I disconnected “Cab 2” and “Valley” since we don’t use them:

Click here to continue reading...

Orion finished the replacement of the T324 turnout that connects the Mainline to the Branchline.

Read this page for all the details and more pictures: 2024-08-21 - Randall Repairs: Turnout T324 on Branchline

The Randall Museum Halloween 2024 event was this Saturday (the museum always does it a bit in advance). Our train operators ran a number of Halloween-themed trains. They dimmed the room lights, for a great ambience:

(photos courtesy of Orion) |

|

They ran 2 Halloween trains with very nice little figurines on the wagons:

Affected |

Turnout T324 (Branchline Angel Camps junction to Mainline). |

Description |

Broken switch rod and points. |

Summary Fix |

Fixed: Replace the turnout. |

Description of Issue

The dual-gauge turnout has two minor issues.

The switch rod broke in 2 parts, and the points are no longer attached to the switch rod anyway. Other than that, it’s awesome. In other words, it’s absolutely unusable as a switch.

I typically do not hesitate to “condemn” turnouts to sidings we never use; however this one is the junction between the mainline and the branchline, and we very much want that to keep working.

Click here to continue reading...

I made a quick attempt at placing Thomas on the (failing) Trolley Automation.

That did not work very long… Thomas worked well there. But like the other trolley units, it had the same problem: as soon as it would stop on the resting point, it would lose conductivity overnight and would not be able to work the next day.

I think there’s something essentially wrong with the track at the end of that spur.

Eventually I will check with Orion about simply changing the rails. There’s not a ton of scenery and almost no ballast there, and it’s easy to access. My first suggestion would be changing the track for something more modern and with better conductivity.

I would also really like to go back to my initial orange trolley with the characteristic sounds and lights. That engine has a LokSound DCC decoder that works fine on the bench, but it fails to reply to start or stop commands “after a while”. And that’s on top of the track becoming a dead spot overnight. I have a few spare decoders I can use for that.

Orion got a dummy Caltrain EMD F40PH. It has a spectacularly primitive “build quality” to it, however it perfectly represents the kind of trains that used to run here in the Bay Area. I opened the engine and added enough weights to it to make it usable, then added that to the Amtrak Branchline Automation train.

I think it’s a good fit:

On the Branchline, block B860 is the YouBet station, and block is a very loooong single block where the branchline loops behind the scenery in the back. With Orion, we added a toggle to be able to turn this part on and off easily:

This allows us to turn this off when we’re not using: if for some reason the Branchline automation train does not strop, I want it to end up “dead” on that spot rather than continue all the way back to the SIA or the Stockton Station.